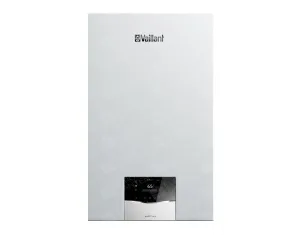

Condensing gas boiler VAILLANT ECOTEC PLUS VU 306-5-5 30 kW

You save: space, energy, time!

The condensation technique represents a very important step in the rational use of energy, recording significant advantages in the exploitation of natural resources and protecting the environment. The energy consumption of thermal power plants with the ecoTEC condensing technique is certainly lower than thermal power plants that use traditional technology. Through the condensation technique, the heat of the water vapor contained in the removed burnt gases is used. Wall-mounted thermal power plants with ecoTEC plus condensing technology operate on natural gas and liquefied petroleum gas (LPG), save up to 30% of energy compared to old boilers, even more than 40% when combined with solar energy and require very little space, being able to be installed easily and quickly in old and new buildings.

Central parts: The central part of the ecoTEC plus is its innovative heat exchanger with a stainless steel thermal layer, offering a water volume of 24 liters. Thanks to the high-quality stainless steel, the exchanger is protected against corrosion and impurities, being resistant and requiring maintenance at longer intervals. This reduces energy consumption and pressure loss, allowing an exceptional efficiency of 110% (PCI).

Advantages of the condensation technique:

Revolutionary air-gas mixture modulation system for increased efficiency

Modulation rate for ecoTEC plus between 1:6 and 1:7

Gas type test program - easy conversion

The new DIA system with display that shows full, illuminated text

Efficient self-adaptive pump for ecoTEC plus

Self-adaptive partial load

Intelligent management of plant functions, including safety and testing programs

Condensing heat exchanger, entirely made of stainless steel

Stainless steel burner

Integrated control of an external heating pump/circulation pump

ProE system

The present comfort function

With all these advantages, thermal power plants using the ecoTEC condensation technique are the ideal choice for those who want to save space, energy and time, without compromising the performance and reliability of the heating system.

| Type: | Condensing |

| Power, kW: | 30,0 |

| Heating surface, m²: | 300 |

| Number of circuits, units: | 1 |

| Combustion chamber type: | Closed (Turbo) |

| Number of heat exchangers, units: | 1 |

| Efficiency, %: | 109 |

| Maximum gas consumption, m³/h: | 3,2 |

| The volume of the expansion vessel, l: | 10 |

| Sizes, mm: | 720x440x372 |

| Weight, kg: | 34,0 |

| Hot water consumption, l/min: | 17,9 |

| Chimney diameter, mm: | 60/100 |

| Maximum pressure, bar: | 3 |

| Heating connection, inch: | 3/4 |

| Water connection, inch: | 1/2 |

| Gas connection, inch: | 3/4 |

| Coutry of brand: | Germany |

| Energy efficiency class: | A |

| Installation method: | Vertical |

| Display: | Yes |

| Destination: | Heating/water supply |

| Color: | White |

| Electrical safety class: | IP X4D |