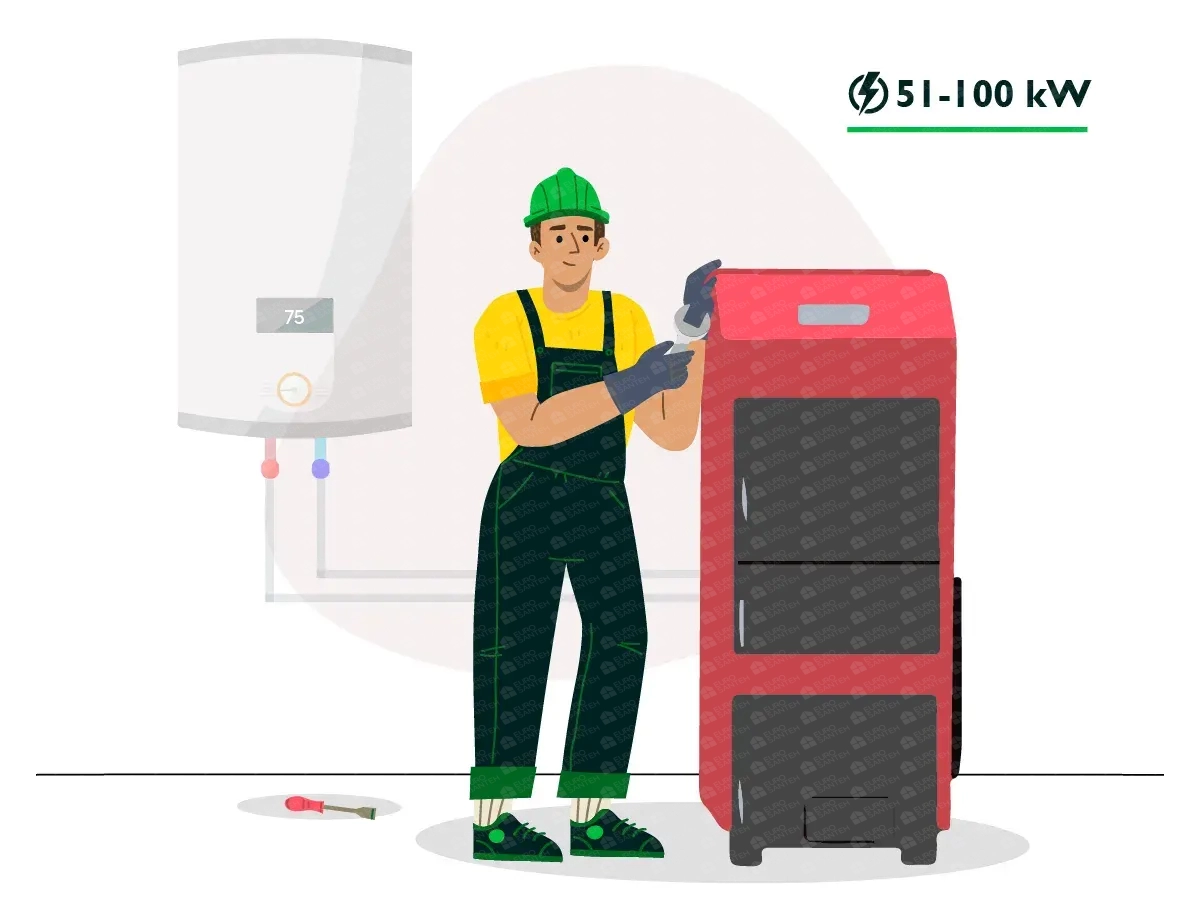

Installation of a solid fuel boiler Kronas in Chisinau

Installing a solid fuel boiler like Kronas is a meticulous process that involves several critical steps to ensure efficient and reliable heating solutions. Kronas boilers are renowned for their robustness and energy efficiency, making them a popular choice for residential and commercial heating needs. Here’s a comprehensive overview of what goes into the installation of a Kronas solid fuel boiler:

Site Assessment and Preparation

The first step in installing a Kronas solid fuel boiler is conducting a thorough site assessment. This includes evaluating the installation site for compliance with safety regulations and building codes. Factors such as ventilation requirements, access to solid fuel sources, and fire protection measures are carefully considered. Proper site preparation ensures the boiler operates efficiently and safely throughout its lifespan.

Assembling and Installing Components

Once the site is prepared, the installation process begins with assembling and installing the boiler components. This includes the boiler unit itself, heat exchanger, water supply and discharge systems, as well as control and safety systems. Each component is assembled according to manufacturer specifications to ensure seamless integration and optimal performance. Proper installation is crucial for maximizing the efficiency and longevity of the Kronas solid fuel boiler.

Ventilation and Exhaust Systems

Installing effective ventilation and exhaust systems is critical for the safe operation of the Kronas solid fuel boiler. Proper ventilation ensures efficient combustion of solid fuels and helps prevent the buildup of harmful gases such as carbon monoxide. Exhaust systems are designed to efficiently remove combustion gases while retaining heat, thereby improving overall energy efficiency.

Integration and Aesthetic Considerations

Beyond functionality, integrating the Kronas solid fuel boiler aesthetically into its surroundings is important. This may involve concealing pipes and electrical components to enhance visual appeal and ensure accessibility for maintenance purposes. Careful integration ensures the boiler complements the existing heating infrastructure while optimizing space utilization.

Testing and Commissioning

Once installation is complete, rigorous testing and commissioning procedures are conducted to verify the functionality and safety of the Kronas solid fuel boiler. This includes pressure testing, calibration of temperature controls, and comprehensive checks for leaks or operational irregularities. Testing ensures the boiler operates reliably under various conditions and meets performance expectations.

User Training and Maintenance Guidelines

Providing comprehensive user training is essential to ensure operators understand how to operate and maintain the Kronas solid fuel boiler effectively. This includes guidance on fuel selection, cleaning schedules, and troubleshooting common issues. Empowering users with knowledge promotes efficient boiler management and extends its operational lifespan.

Conclusion

In conclusion, the installation of a Kronas solid fuel boiler requires meticulous planning, precise execution, and adherence to safety standards. By following these steps, homeowners and businesses can enjoy reliable heating solutions that are energy-efficient and cost-effective. Each stage of the installation process contributes to the overall performance and durability of the Kronas solid fuel boiler, ensuring comfort and efficiency for years to come.