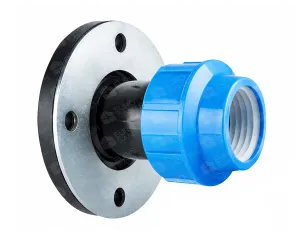

Polyethylene pipes and fittings PE

Polyethylene (PE) pipes and fittings have emerged as essential components in various industries, offering versatile solutions for fluid transportation and distribution. This comprehensive guide explores the key features, applications, benefits, and considerations associated with Polyethylene pipes and fittings, shedding light on their crucial role in modern construction and infrastructure.

Key Features of Polyethylene Pipes and Fittings:

Chemical Resistance: PE pipes and fittings exhibit excellent resistance to a wide range of chemicals, ensuring the integrity of the system in diverse environments.

Corrosion Resistance: Unlike metallic counterparts, polyethylene is corrosion-resistant, mitigating the risk of leaks and extending the overall lifespan of the infrastructure.

Flexibility and Lightweight: The lightweight and flexible nature of PE pipes facilitates easy handling, reducing labor costs and simplifying installation processes.

Durability and Longevity: Polyethylene's innate durability ensures the pipes and fittings withstand harsh conditions, maintaining structural integrity over an extended period.

Applications of Polyethylene Pipes and Fittings:

Water Supply Systems: PE pipes are widely used in water supply systems, ensuring a safe and leak-free delivery of potable water.

Gas Distribution Networks: Polyethylene's safety and corrosion resistance make it an ideal material for gas distribution networks, guaranteeing efficient and secure transportation of natural gas.

Industrial Fluid Transport: In industrial settings, PE pipes play a crucial role in transporting various fluids, thanks to their chemical resistance and durability.

Agricultural Irrigation: The flexibility and durability of PE pipes make them suitable for agricultural irrigation systems, promoting efficient water distribution in fields.

Benefits of Using Polyethylene Pipes and Fittings:

Corrosion Resistance: A fundamental advantage of PE pipes is their resistance to corrosion, ensuring the system's longevity.

Ease of Installation: The lightweight nature and flexibility of polyethylene pipes contribute to straightforward installation processes, reducing labor costs and project timelines.

Leak Prevention: Fittings designed for polyethylene pipes ensure secure and leak-resistant joints, minimizing the risk of fluid leakage.

Cost-Effectiveness Over Time: While the initial cost might be higher, the lower maintenance costs and extended lifespan make PE pipes a cost-effective choice in the long run.

Considerations when Using Polyethylene Pipes and Fittings:

Professional Installation: To maximize the benefits, it's advisable to have polyethylene pipes and fittings installed by experienced professionals familiar with working with this material.

Pressure and Temperature Limits: Adhering to recommended pressure and temperature limits is crucial to preventing system failures and maintaining the performance of polyethylene pipes.

Material Compatibility: Ensure that the chosen polyethylene pipes and fittings are compatible with the specific fluids being transported to avoid adverse reactions or degradation.

Quality Assurance: Purchase pipes and fittings from reputable suppliers to guarantee product authenticity and adherence to quality standards.

Procuring Polyethylene Pipes and Fittings:

Specialized Suppliers: Seek out specialized suppliers or construction material stores that offer a diverse range of polyethylene pipes and fittings, along with expert guidance.

Manufacturer Recommendations: Consider purchasing from manufacturers recommended by industry professionals to ensure the authentic quality of polyethylene products.

Online Platforms: Explore online platforms for convenient access to a variety of polyethylene pipes and fittings, enabling easy product comparison and price evaluation.

Authorized Distributors: Buy from authorized distributors to guarantee the authenticity of polyethylene products and compliance with quality standards.

Maintenance and Upgrades:

Regular Inspections: Conduct periodic inspections of polyethylene pipes to identify signs of wear or potential issues, addressing them promptly.

Replacement of Worn Components: Replace any worn-out or damaged polyethylene pipes and fittings to maintain system efficiency and integrity.

Performance Monitoring: Periodically check pressure and flow rates to make adjustments as needed, ensuring the efficient operation of the polyethylene pipe system.

Adherence to Evolving Standards: Stay informed about industry standards and regulations, upgrading the system when necessary to comply with the latest requirements.

Conclusion: Polyethylene Pipes and Fittings - A Pinnacle in Fluid Transportation:

Polyethylene pipes and fittings stand as a pinnacle in modern fluid transportation and distribution systems. Investing in polyethylene ensures resilience, longevity, and sustainability across various applications. As you integrate these innovative solutions, you contribute to the construction of a robust, reliable, and forward-thinking infrastructure. Polyethylene pipes and fittings represent not only a technological advancement but also a commitment to efficiency and durability in fluid transport systems.