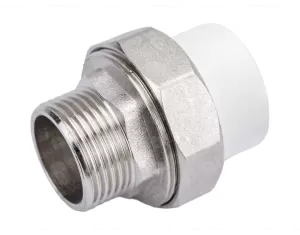

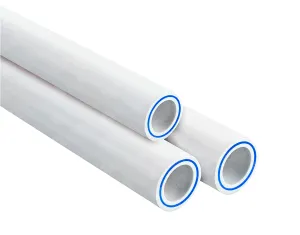

Polypropylene PPR pipes and fittings

Polypropylene (PPR) pipes and fittings have emerged as a revolutionary solution in the field of fluid transport systems, offering a myriad of advantages in terms of durability, versatility, and ease of installation. This comprehensive exploration delves into the key features, applications, benefits, and considerations associated with Polypropylene PPR pipes and fittings, highlighting their indispensable role in modern construction and plumbing.

Key Features of Polypropylene PPR Pipes and Fittings:

Chemical Resistance: PPR pipes and fittings exhibit exceptional resistance to a wide range of chemicals, ensuring stability and integrity in various fluid transport environments.

Heat Resistance: With high tolerance to elevated temperatures, Polypropylene PPR is well-suited for applications involving hot water transport, making it a preferred choice in plumbing and heating systems.

Lightweight and Flexible: The lightweight nature and flexibility of PPR pipes simplify handling and installation, reducing labor costs and making them suitable for various construction projects.

Longevity and Durability: PPR pipes and fittings boast a long service life, resisting corrosion, rust, and degradation even in challenging conditions, contributing to the sustainability of fluid transport systems.

Applications of Polypropylene PPR Pipes and Fittings:

Plumbing Systems: PPR pipes are widely used in plumbing installations for both residential and commercial buildings, ensuring a reliable and leak-free water supply.

Heating Systems: The heat resistance of PPR pipes makes them ideal for use in heating systems, efficiently transporting hot water without compromising performance.

Industrial Fluid Transport: PPR pipes find applications in various industrial settings where chemical resistance and durability are paramount, facilitating the safe transport of fluids.

Agricultural Irrigation: In agriculture, PPR pipes are employed for irrigation systems, providing a robust and corrosion-resistant solution for water distribution.

Benefits of Polypropylene PPR Pipes and Fittings:

Corrosion Resistance: PPR's inherent resistance to corrosion ensures that the pipes and fittings maintain their structural integrity over time, minimizing the need for maintenance.

Easy Installation: The lightweight and flexible nature of PPR pipes simplifies the installation process, reducing labor costs and allowing for quick and efficient assembly.

Leak-Free Joints: PPR fittings, when properly installed, create secure and leak-free joints, enhancing the overall reliability of the fluid transport system.

Cost-Effective Solution: While the initial cost of PPR pipes and fittings might be higher than some alternatives, their durability and low maintenance requirements contribute to long-term cost-effectiveness.

Considerations When Using Polypropylene PPR Pipes and Fittings:

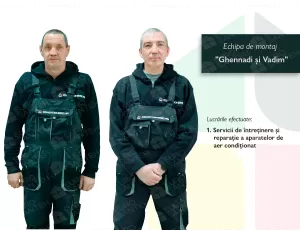

Professional Installation: To maximize the benefits of PPR pipes, it is advisable to enlist the services of professionals who are experienced in working with this material.

Compatibility: Ensure that PPR pipes and fittings are compatible with the specific fluids being transported to avoid any adverse reactions or deterioration.

Pressure and Temperature Ratings: Adhere to the recommended pressure and temperature ratings to prevent system failures and maintain the performance of PPR pipes and fittings.

Quality Assurance: Source PPR pipes and fittings from reputable manufacturers to ensure compliance with industry standards and the use of high-quality materials.

Purchasing Polypropylene PPR Pipes and Fittings:

Specialized Suppliers: Seek out specialized suppliers or plumbing supply stores that offer a diverse range of PPR pipes and fittings, along with expert guidance.

Manufacturer Recommendations: Consider purchasing from manufacturers recommended by industry professionals to ensure product quality and authenticity.

Online Platforms: Explore online platforms for convenient access to a wide selection of PPR pipes and fittings, allowing for easy comparison of products and prices.

Authorized Distributors: Purchase from authorized distributors to guarantee the authenticity of the PPR products and adherence to quality standards.

Maintenance and Enhancements:

Regular Inspection: Periodically inspect PPR pipes and fittings for signs of wear, damage, or potential issues, addressing any concerns promptly.

Replacement of Worn Components: Replace any PPR pipes or fittings that show signs of wear or aging to maintain the efficiency and integrity of the fluid transport system.

Monitoring System Performance: Monitor system performance by checking pressure levels and flow rates, making adjustments as needed to ensure optimal operation.

Anti-Corrosion Measures: In areas with hard water or corrosive conditions, consider implementing anti-corrosion measures to prolong the life of PPR pipes and fittings.

Conclusion: Polypropylene PPR Pipes and Fittings - The Future of Fluid Transport Systems:

In conclusion, Polypropylene PPR pipes and fittings represent a technological advancement that has transformed the landscape of fluid transport systems. Their combination of chemical resistance, heat tolerance, and ease of installation makes them a preferred choice for plumbing, heating, and industrial applications. By adhering to best practices in installation, maintenance, and sourcing, PPR pipes and fittings provide a reliable and efficient solution for fluid transport in various sectors. As the demand for sustainable and durable materials continues to rise, Polypropylene PPR pipes and fittings stand as a testament to innovation in the construction and plumbing industry.