Solid fuel boiler with automatic loading DEFRO KOMFORT EKO LUX 40 kW

The Defro Komfort Eko Lux automatic solid fuel boiler is equipped with an automated fuel feeding system that delivers fuel into the combustion zone and features a robust retort burner made of heat-resistant cast iron, ensuring durability and stable operation.

The heat exchanger in this boiler is constructed from high-strength, heat-resistant P265GH Arcelor Mittal steel, with a thickness of 6–8 mm, achieving efficiency levels of up to 88%. As an insulating material, mineral basalt wool is placed between the boiler casing and the heat exchanger, as well as in the combustion chamber doors. This guarantees safety by eliminating the risk of burns upon accidental contact with external metal surfaces.

Defro Komfort Eko Lux is equipped with a spacious fuel hopper, designed for use with granular fuels such as pellets or coal (5–25 mm fraction), allowing the boiler to operate autonomously for 3–5 days. The burner has a bowl-shaped design, optimized for efficient combustion, while a screw mechanism automatically feeds fuel into the combustion chamber. The forced supply of primary air stabilizes the combustion process and prevents the burner from overheating.

Additionally, secondary air is introduced into the combustion zone through special air ducts, ensuring complete fuel combustion and minimal ash formation, which is automatically removed as new fuel portions are supplied.

To enhance efficiency, the boiler incorporates a multi-point air supply system combined with a self-cleaning nozzle function. This ensures uniform and prolonged combustion while stabilizing the boiler’s operating parameters.

Exhaust gases are discharged through a flue located at the rear of the boiler, with an integrated damper that allows draft regulation, enabling precise control over the combustion intensity. The well-thought-out design ensures quick and effortless maintenance of the heat exchanger and flue channels.

The boiler is controlled via a modern weather-dependent controller, which regulates the operation of four pumps (central heating, domestic hot water, and two additional circuits), as well as a mixing valve. The controller supports connectivity to GSM and internet modules, allowing remote management. Additionally, an SPK Lux room thermostat can be integrated. Software updates for the controller can be performed via USB, downloading the latest version from the manufacturer’s official website.

Although the Defro Komfort Eko Lux is a single-circuit boiler, it can be connected to an indirect water heater, ensuring hot water supply throughout the year. The use of a circulation pump speeds up the heating process. Installation is simple and does not require complex assembly, making it possible to set up either independently or with professional assistance.

Advantages of Defro Komfort Eko Lux:

High efficiency of up to 88%, thanks to the optimized heat exchanger design.

Automatic fuel feeding and forced air injection for stable combustion.

Easy maintenance – self-cleaning nozzle system and quick access to the heat exchanger and flue.

Spacious fuel hopper, providing 3–5 days of autonomous operation.

Smart controller with remote management support via GSM and internet.

Option to connect an indirect water heater for domestic hot water supply.

Quick and easy installation, without requiring complex assembly work.

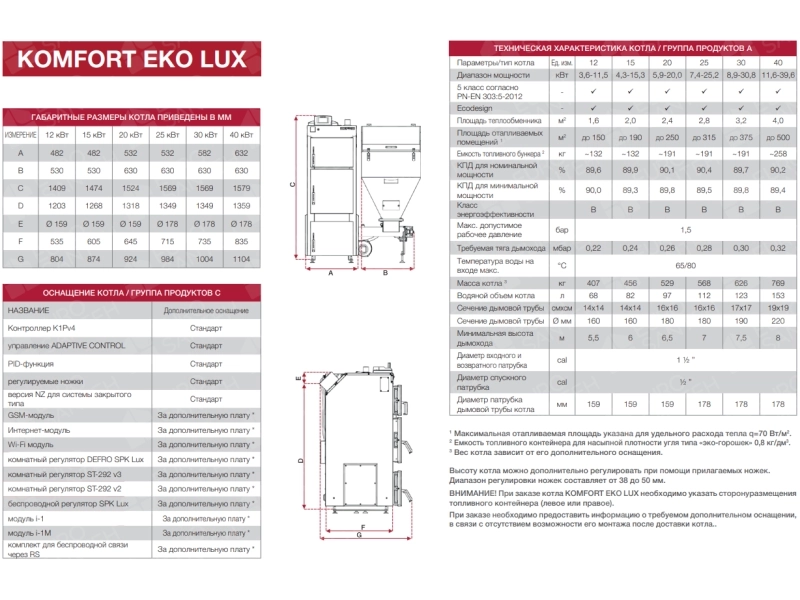

| Power, kW: | 40,0 |

| Heating surface, m²: | 400 |

| Loading type: | Automatic |

| Efficiency, %: | 90 |

| Metal thickness, mm: | 6,0 |

| Hopper volume, l: | 258 |

| Boiler water volume, litres : | 153 |

| Weight, kg: | 769,0 |

| Height, mm: | 1579 |

| Width, mm: | 1330 |

| Depth, mm: | 1104 |

| Maximum pressure, bar: | 1,5 |

| Combustion chamber type: | Open |

| Fuel type: | Solid |

| Chimney diameter, mm: | 220 |

| Number of circuits, units: | 1 |

| Installation method: | On the floor |

| Coutry of brand: | Poland |

| Destination: | Heating |

| Exit from the heating system: | 1/2 |

| Entering the heating system: | 1/2 |

| Automatic loading: | Yes |

| Single load, kg: | 258 |