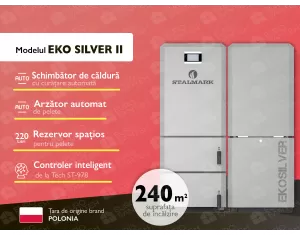

The STALMARK EKO SILVER boiler is an advanced development by STALMARK, equipped with a fully automated control system, start/stop function (ignition/extinguishing), mechanical burner cleaning system, and vertically positioned tubular heat exchanger.

The main element of the boiler is an innovative burner with a movable grate that automatically cleans the combustion chamber, ensuring stable operation even when using low-quality pellets. The combustion process is monitored by a photocell, which ensures the controller receives timely information about the burner's condition and accurately determines when cleaning, activation of the heating coil, or maintenance of the smoldering is required.

A significant advantage of the design is the vertical placement of the chamotte plates and heat exchanger tubes. During boiler cleaning, ash falls between the plates directly into the ashtray, significantly simplifying maintenance — it is enough to empty the ashtray once or twice a week.

The boiler efficiency reaches 91.3%, corresponding to energy efficiency class A+.

The automatic heating system minimizes the need for user intervention: the boiler can operate without refueling for 3–4 to 7–10 days, depending on the loading tank volume.

Construction:

The boiler body is made of certified boiler steel with a thickness of 6 mm, ensuring reliability and durability (warranty up to 48 months). The standard package includes adjustable legs for easy installation, a fuel tank with the possibility of installation on the right or left side, and a boiler door.

The main vertical heat exchanger, located at the top of the structure, makes the boiler more compact.

The automated cleaning system using spirals ensures efficient operation of the heat exchanger.

The ST-978 controller, included in the package, controls the blower fan, two fuel feeders, radiator heating pumps, hot water system (boiler), and floor and circulation pumps.

Additionally, control of the room thermostat (both standard type and remote control) is supported, as well as the GSM modules ST-65 and internet module ST-505.

Control of the 3- or 4-way valve is carried out as standard, with the possibility of expansion to three additional drives.

If necessary, the boiler can be equipped with a LAMBDA probe for precise control of the combustion gas composition and optimization of the combustion process, as well as increasing the loading tank volume.

Main features of the ST-978 T control unit:

modern design and user-friendly interface;

control of the combustion process and maintaining stable temperature;

control of heating, hot water supply, and circulation pumps;

possibility of connecting an internet module;

control of mixing valves (one built-in, two additional with I-1 module expansion);

operation with equithermal control, thermostat, or set time;

integration with the wireless room thermostat 281 C, which allows remote control of the boiler operation, receiving notifications about alarm events, and monitoring the fuel level in the tank.

| Power, kW: | 24,0 |

| Heating surface, m²: | 240 |

| Loading type: | Automatic |

| Efficiency, %: | 92,2 |

| Metal thickness, mm: | 6,0 |

| Hopper volume, l: | 220 |

| Boiler water volume, litres : | 92 |

| Weight, kg: | 385,0 |

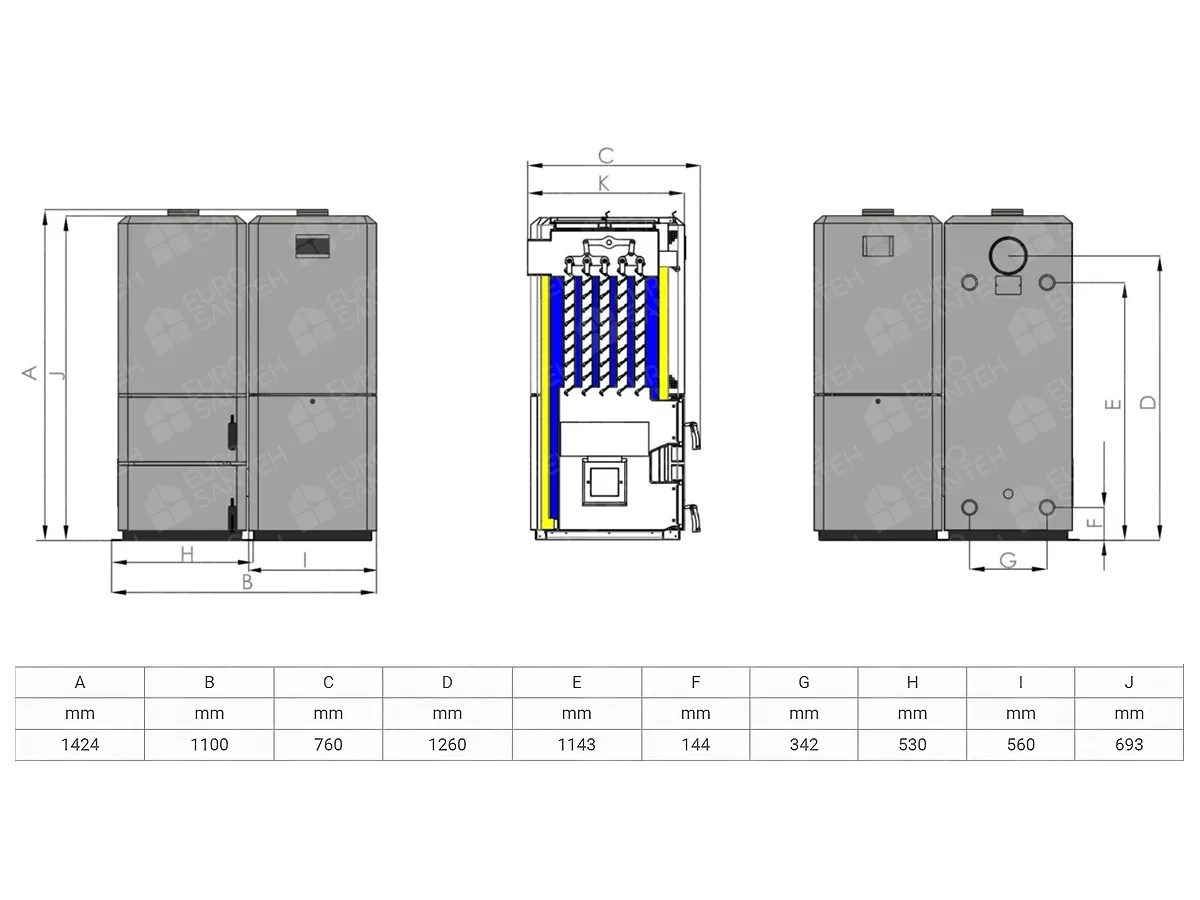

| Height, mm: | 1424 |

| Width, mm: | 1100 |

| Depth, mm: | 760 |

| Maximum pressure, bar: | 1,5 |

| Combustion chamber type: | Open |

| Fuel type: | Wood pellets |

| Chimney diameter, mm: | 180 |

| Installation method: | On the floor |

| Coutry of brand: | Poland |

| Destination: | Heating |

| Exit from the heating system: | 1 |

| Entering the heating system: | 1 |

| Automatic loading: | Yes |