Structural Features of Almax Class C

Almax Class C (КТК) boilers with a power range of 12-38 kW are made from special boiler steel with a thickness of 5 mm, ensuring reliable protection of internal components against corrosion. The design features double walls separated by water partitions, allowing for even heat distribution.

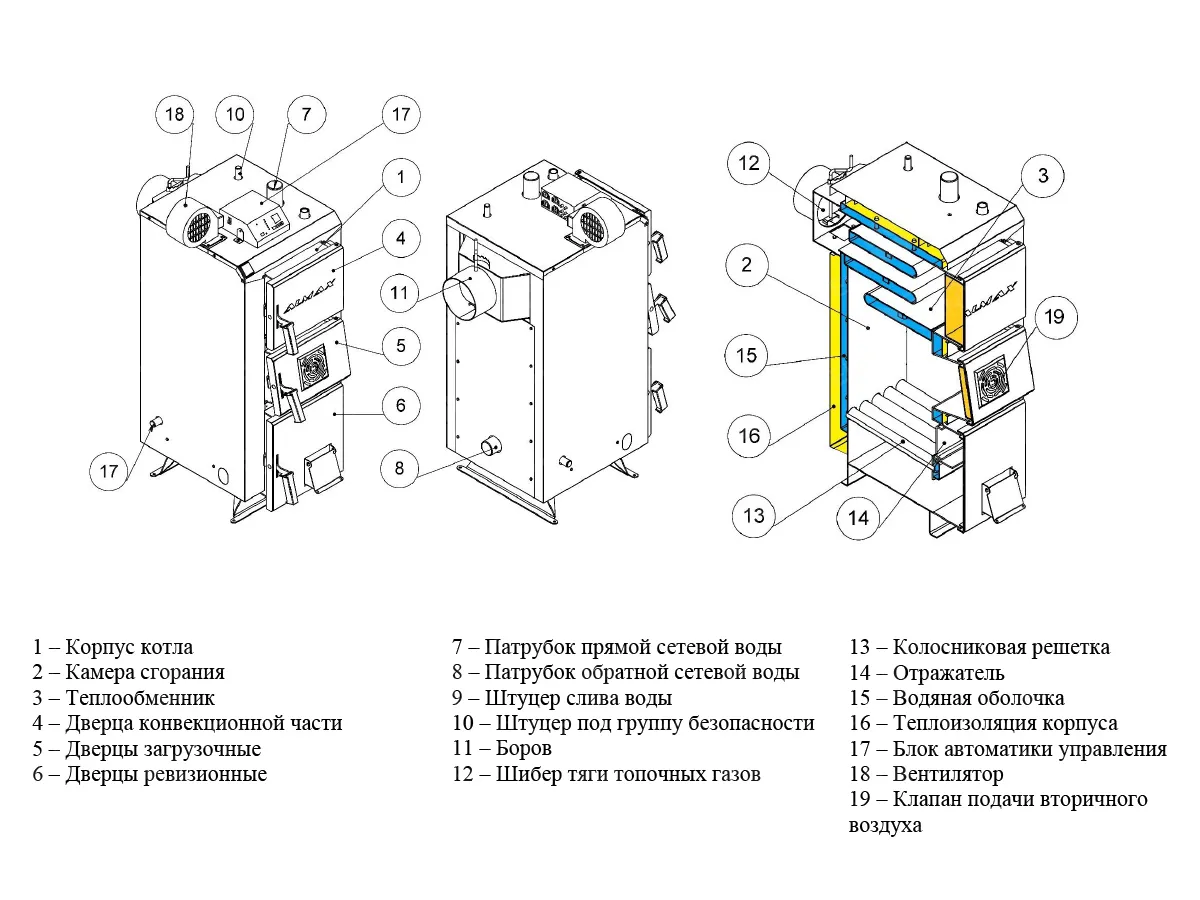

The main components of the boiler include:

- A two-pass heat exchanger for efficient heat transfer.

- A spacious combustion chamber, with volume varying by model.

- Grates made of seamless pipes for fuel placement.

- An optimally sized loading door for convenient fuel addition.

- Inlet and outlet pipes for connecting to the heating system.

- Additional pipes for quick water drainage and safety group installation.

- Service doors for heat exchanger maintenance.

- A revision door for servicing the grates.

- An optional grate cleaning mechanism.

Almax Class C boilers come with a control unit that monitors water temperature. This system regulates fan operation, and an optional circulation pump can be added for automatic heat carrier circulation.

Advantages of Almax Class C Boilers

The operating temperature of the Almax Class C boiler is set via an automatic control panel. The optimally sized combustion chamber ensures efficient fuel usage to maintain the desired temperature.

Key Benefits:

✔ High efficiency – at least 85%, depending on the type of fuel used.

✔ Effective convection – horizontal multi-pass heat exchanger.

✔ Reliable protection – the casing is equipped with a decorative cover and thermal insulation layer.

✔ Premium materials – heat exchanger and casing made from high-temperature-resistant European boiler steel (5 mm internal, 3 mm external).

✔ Energy independence – compatible with a mechanical draft regulator.

✔ Secondary air injection nozzles for improved fuel combustion.

✔ User-friendly operation – multiple doors for fuel loading, ash removal, and heat exchanger maintenance.

✔ Versatile fuel options – supports wood, coal, and fuel briquettes.

✔ Long burning duration – wood 5-10 hours, briquettes 10-15 hours, coal up to 24 hours or more.

✔ Modern design – powder-coated finish.

✔ Durability – boiler lifespan of at least 15 years.

✔ Compact and practical – ideal for limited-space installations.

Operational Features

Almax Class C long-burning boilers are designed for heating residential, commercial, and industrial buildings. Depending on power output, they can heat spaces ranging from 60 to 380 m².

Supported fuel types:

✅ Firewood

✅ Coal

✅ Fuel briquettes (wood or peat-based)

Additionally, wood processing industry waste can be used as fuel. However, the highest efficiency is achieved when burning coal. The boiler’s design allows for the effective use of low-calorie fuel while still providing sufficient heat output.

Almax Class C is a reliable and cost-effective heating solution, combining high efficiency, ease of use, and long service life.

| Power, kW: | 14,0 |

| Heating surface, m²: | 140 |

| Loading type: | Manual |

| Efficiency, %: | 85 |

| Metal thickness, mm: | 5,0 |

| Boiler water volume, litres : | 50 |

| Weight, kg: | 161,0 |

| The volume of the combustion chamber, l: | 41 |

| Height, mm: | 1175 |

| Width, mm: | 510 |

| Depth, mm: | 905 |

| Maximum pressure, bar: | 2 |

| Combustion chamber type: | Open |

| Fuel type: | Solid |

| Chimney diameter, mm: | 160 |

| Installation method: | On the floor |

| Coutry of brand: | Ucraine |

| Destination: | Heating |

| Exit from the heating system: | 2 |

| Entering the heating system: | 2 |

| Automatic loading: | No |