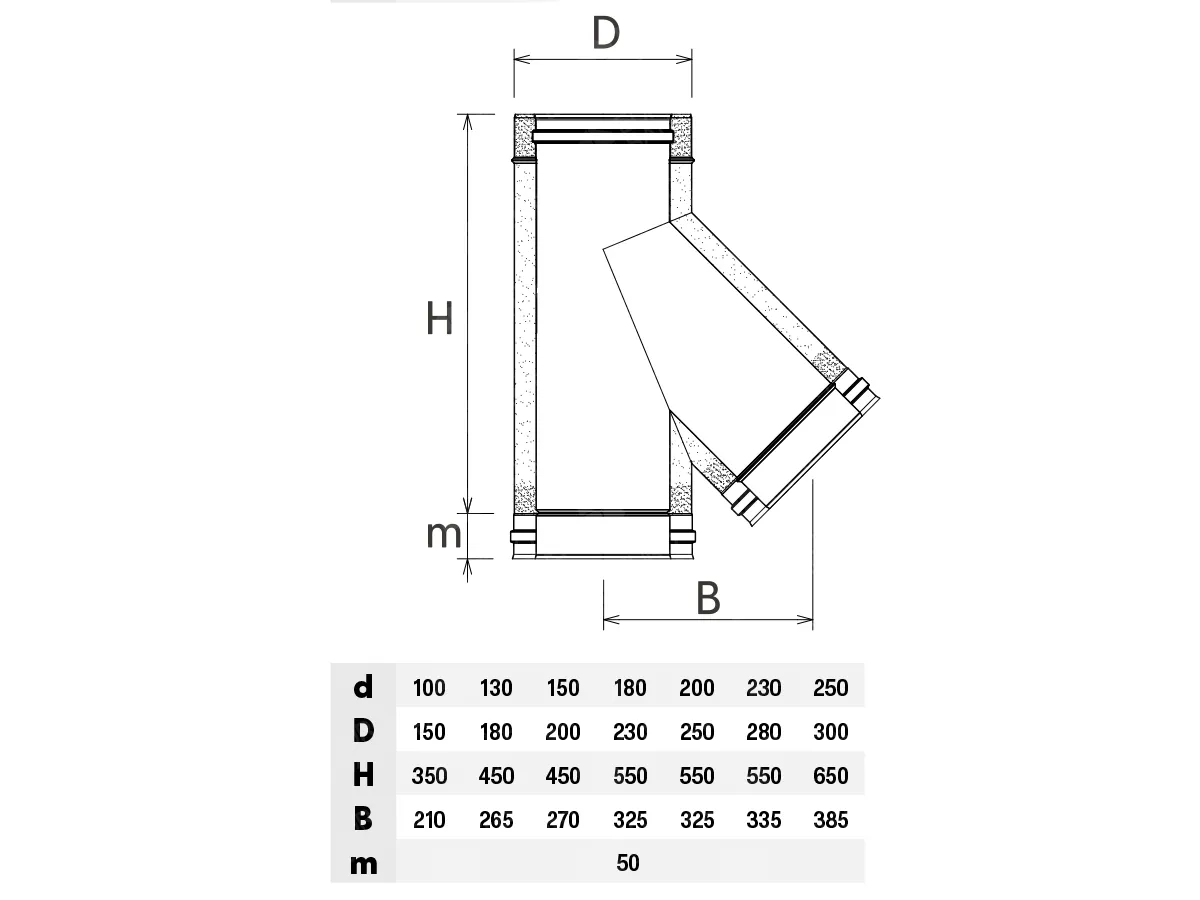

Insulated 135° chimney tee SOLINOX Ø200–250 (inox 304/304)

The insulated 135° chimney tee SOLINOX Ø200-250 (inox 304/304) is a double-wall “sandwich” component designed to connect a vertical run with a horizontal (or inclined) section of a flue system. It is selected when the goal is not only to create a branch, but also to preserve flue-gas temperature and maintain stable draft on more demanding routes. With a 135° angle, the flow negotiates the turn more smoothly than with a 90° tee, reducing resistance and delivering steadier, more predictable draft—especially during start-up and at partial output.

The “sandwich” design consists of an inner and outer pipe made of stainless steel inox 304 (304/304) with a thermal-insulation layer between them. The insulation is what makes this node particularly valuable: it limits flue-gas cooling, helps reduce condensate formation, and protects nearby structures from excessive surface temperature. The practical benefit is fewer “wet” deposits and a lower risk of condensate flowing back toward the heating appliance. That is why insulated tees are often chosen for sections running through cold zones (unheated rooms, attics, outdoor runs) or wherever draft stability is critical under temperature swings.

A 135° branch connection supports better draft behavior than a 90° tee—most noticeable on chimneys with multiple turns or where overall height is limited. The Ø200-250 range is convenient for joining elements of different diameters and for systems where a larger main-channel capacity is required by design calculation. This format is commonly used when connecting higher-output boilers, stoves, and fireplaces, as well as when upgrading existing chimneys where a proper tie-in to the vertical line is needed.

Installation is quick and neat thanks to the socket (spigot-and-socket) connection: components mate without complex operations, and tightness is achieved through correct joint orientation and clamp fixing. In flue systems, it is essential to assemble sections so that condensate and combustion by-products do not escape through joints and do not enter living spaces. The insulated SOLINOX tee helps meet this requirement by maintaining temperature and reducing the likelihood of “dew point” conditions at the turn.

The lower section of the tee is a mandatory service zone. Beneath the tee, an inspection section, an end cap, or a condensate collector should be installed. This provides access for cleaning, allows monitoring of the flue channel condition, and enables safe removal of moisture and deposits that can accumulate at the lowest point of the assembly. Properly organized inspection access simplifies maintenance and extends the service life of the entire system.

SOLINOX Ø200-250 (inox 304/304) is an optimal option if you need an insulated 135° tee for a double-wall chimney with a focus on draft performance, thermal stability, and condensate protection. It suits flue systems of any complexity, makes side-branch connection to the main channel easier, and helps ensure calmer, safer long-term operation.

| Operating temperature, °C: | +200...+300 |

| Type: | Chimney tee 45°/135° |

| Internal diameter, mm: | 200 |

| Tip izolare: | Isolated |

| External diameter, mm: | 250 |

| Metal thickness, mm: | 0,5 |

| Stainless steel internal layer, AISI: | 304 |

| External layer stainless steel, AISI: | 304 |

| Coutry of brand: | Turkey |

| Color: | Silver |

| Scope of application of the chimney: | Boilers, fireplaces, stoves |