Bimetallic radiators

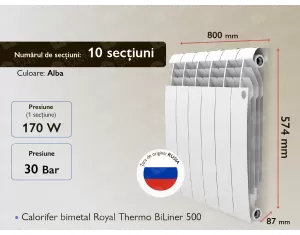

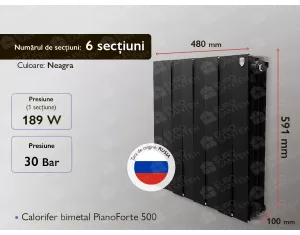

Bimetallic radiators are selected for apartments with centralized heating, for houses with variable load, and for offices where stable daytime heat distribution is required; in practice, teams compare sectional models by section count and operating pressure. In Chisinau and across Moldova, some options are available in stock and others are supplied on order, so price guidance and delivery timelines are aligned with heat loss, system parameters, and connection layout.

Before fitting, teams verify connection distance, inlet type, operating pressure, heat-carrier quality, valves, and service access. Wrong selection often causes uneven heating and repeated adjustments after startup.

The practical workflow is heat sizing, compatibility validation, fitting, balancing, and live-load checks.

When bimetallic radiators are the right fit

This solution is used when pressure resilience, predictable thermal mode, and clean integration into an existing heating loop are required.

What parameters drive selection

Core parameters are heat loss, operating pressure, section count, connection layout, and usage profile. For daily seasonal use, adjustment and service planning should be set upfront.

Installation, startup, and stable operation

Before works begin, teams fix connection points and valve layout; after fitting, venting and balancing are completed. Operation is then verified under real load and service terms are agreed.

What else matters in selection

For parent-level comparison, teams usually start from radiators and heating batteries and then narrow material choice. If a compact panel format is needed, they compare steel radiators by mounting scheme. For lighter units and fast thermal response, they review aluminum radiators. In projects with visual focus, they also evaluate designer radiators.

Frequently asked questions

What properties are bimetallic radiators suitable for?

For apartments, houses, and offices that need stable seasonal operation and pressure resilience.

What is checked before selection?

Heat loss, system pressure, section count, connection format, and heat-carrier parameters.

Can selection and installation be delivered in one workflow?

Yes, selection, fitting, and startup checks can be coordinated in one process.

How can uneven heating risk be reduced?

By accurate sizing, proper connection layout, and balancing after installation.

Is service available after startup?

Yes, maintenance terms are fixed when project conditions are confirmed.