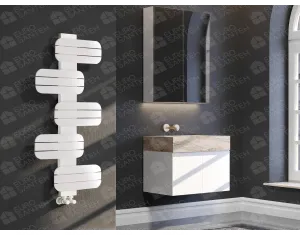

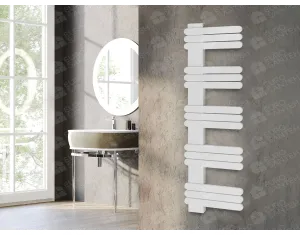

Designer towel rails

Designer towel rails are selected for apartments with strong bathroom interior focus, for houses with custom connection layout, and for hotel projects where style and predictable heating must coexist; in practice, teams compare models by center distance, connection type, finish, and heating mode. In Chisinau and across Moldova, some options are available in stock and others are supplied on order, so price guidance and delivery timelines are aligned with technical parameters and installation constraints.

Before fitting, teams verify connection compatibility, operating pressure, material, valve set, mounting points, and service access. Wrong selection often causes installation delays and repeated visits after startup.

The practical workflow is parameter check, model selection, installation, initial adjustment, and live-load control.

When designer models are the right fit

This solution is used where the towel rail must deliver practical heating value while acting as a visible design element in the bathroom.

What parameters drive selection

Core parameters are connection type, center distance, operating pressure, material, finish, and heating mode. For daily use, maintenance and node access should be planned upfront.

Installation, startup, and stable operation

Before works begin, teams define the connection layout and valve set; after fitting, tightness and adjustment are verified. The system is then tested under load and service terms are aligned.

What else matters in selection

For parent-level comparison, teams usually start from towel warmers and then refine to designer format. For component setup they review accessories for radiators. For broader comparison they check radiators and heating batteries. In visual-led projects they also evaluate designer radiators.

Frequently asked questions

What properties are designer towel rails suitable for?

For apartments, houses, hotels, and commercial bathrooms where both style and stable heating are required.

What is checked before selection?

Connection type, center distance, operating pressure, material, finish, and system parameters.

Can selection and installation be delivered in one workflow?

Yes, selection, fitting, and startup checks can be coordinated in one process.

How can repeated post-install visits be reduced?

By verifying connection compatibility, full valve set, and initial adjustment after fitting.

Is service available after startup?

Yes, maintenance terms are fixed when project conditions are confirmed.