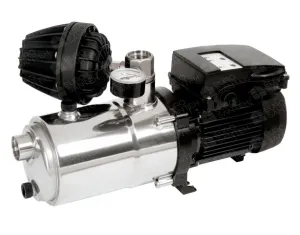

Centrifugal, surface pumps

Centrifugal surface pumps represent a cornerstone in fluid transfer technology, offering efficient and versatile solutions for a wide range of applications. Renowned for their simplicity, reliability, and adaptability, these pumps play a pivotal role in various industries and domestic settings where the movement of liquids is a critical requirement.

Key Features of Centrifugal Surface Pumps:

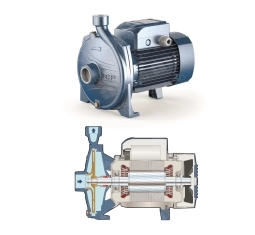

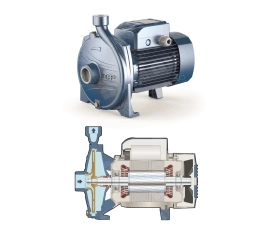

1. Centrifugal Force Principle:

Centrifugal surface pumps operate on the principle of utilizing centrifugal force to propel fluids. The rapid rotation of the impeller generates a centrifugal force that moves the liquid outward, creating a continuous and efficient flow.

2. Surface Pump Design:

Surface pumps are specifically designed to operate at or near the surface of the liquid being pumped. This makes them well-suited for applications where water needs to be lifted from a shallow source, such as wells or reservoirs.

3. Versatility in Applications:

From domestic water supply systems to agricultural irrigation and industrial processes, centrifugal surface pumps showcase versatility by efficiently handling various liquids and contributing to fluid management across diverse sectors.

Applications of Centrifugal Surface Pumps:

1. Domestic Water Supply:

Centrifugal surface pumps are widely employed in providing water for households and communities. They excel in lifting water from shallow sources, ensuring a reliable water supply for daily needs.

2. Agricultural Irrigation:

In agriculture, these pumps play a vital role in irrigating fields. Their ability to lift water to moderate heights makes them suitable for ensuring proper hydration of crops in diverse farming applications.

3. Industrial Processes:

Centrifugal surface pumps find extensive use in industrial processes that require the transfer of liquids. Their adaptability to various liquids and ease of operation make them indispensable in manufacturing and industrial settings.

Selecting and Installing Centrifugal Surface Pumps:

1. Determining Specific Requirements:

Before selecting a centrifugal surface pump, it is crucial to assess the specific requirements of the application, including the necessary flow rate, pressure, and the type of liquid to be pumped.

2. Choosing the Right Model:

Centrifugal surface pumps come in a variety of models, each designed for specific conditions. Choosing the right model involves considering factors such as pump capacity, head, and efficiency to ensure optimal performance.

3. Professional Installation:

For optimal performance and longevity, it's recommended to have centrifugal surface pumps professionally installed. Proper positioning and connection to the water source are critical for achieving efficient fluid transfer.

Advantages of Centrifugal Surface Pumps:

Efficiency and Reliability: Centrifugal surface pumps are known for their high efficiency and reliability in delivering a consistent flow of water. Their straightforward design contributes to ease of use and maintenance.

Cost-Effective Solutions: These pumps often provide cost-effective solutions for water transfer needs. Their relatively simple construction makes them accessible and practical for various budget considerations.

Low Maintenance Requirements: Centrifugal surface pumps generally have low maintenance requirements. Regular checks on the impeller and motor components can help ensure continued efficiency.

Conclusion: Versatile Fluid Transfer with Centrifugal Surface Pumps:

Centrifugal surface pumps stand as versatile and reliable tools for fluid transfer in a multitude of applications. Whether providing water for households, supporting agricultural practices, or contributing to industrial processes, these pumps demonstrate efficiency, adaptability, and a crucial role in fluid management systems globally. The careful selection and proper installation of centrifugal surface pumps contribute to their effectiveness, ensuring a consistent and reliable flow of liquid for a multitude of purposes.