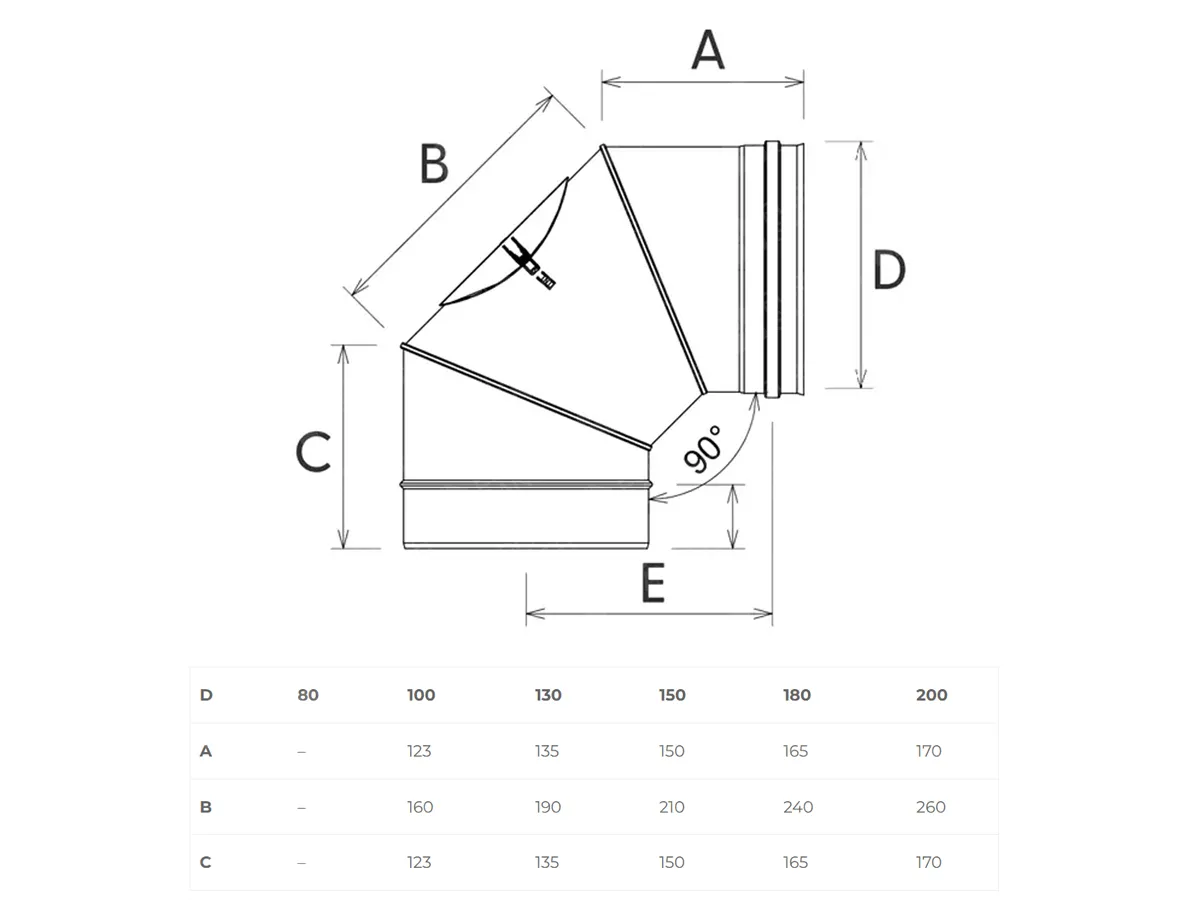

90° chimney elbow with inspection opening SOLINOX Ø180 (inox 304)

The SOLINOX 90° Ø180 chimney elbow with an inspection port is a flue-system component that turns the run by 90 degrees while also providing service access at the bend. Flow restriction most often develops at turns: the airflow direction changes, solid particles settle more actively, and moisture forms faster when the channel cools. The inspection hatch addresses a practical need — it lets you inspect and clean the section without dismantling the route or removing adjacent components.

This version is made from stainless steel AISI 304 (inox 304). It is a widely used chimney material, resistant to corrosion in humid environments and to temperature swings during regular operation. Grade 304 is well suited for systems where the main risk is not highly aggressive chemical condensate, but general conditions such as ambient humidity, repeated heating/cooling cycles, and the need to maintain joint tightness over the long term.

The Ø180 mm diameter is selected when a larger flue cross-section is required. This is relevant for higher-output stoves and boilers, for longer runs, and for cases where it is important to reduce resistance to flue-gas removal. At the same time, a 90° turn inevitably adds flow resistance — an engineering trade-off: compact routing and easier layout in exchange for higher requirements on keeping the channel clean. The inspection version helps offset this in real use: maintenance becomes fast and regular, and the channel condition can be monitored without disassembly.

The inspection cover is convenient for scheduled cleaning and checks: you can remove deposits in the elbow area, assess the inner surface condition, and confirm there are no obstructions to normal flue-gas passage. This is especially important in shoulder seasons and during “short firing” regimes, when the chimney does not fully warm up along its length and condensate formation is more frequent.

The SOLINOX Ø180 90° elbow with inspection is used in modular stainless-steel chimney systems and is compatible with matching-diameter components such as straight pipes, tees, adapters, supports, and mounting elements. It is chosen when a route turn is required while keeping controllable servicing at the most demanding point of the chimney.

| Operating temperature, °C: | +200...+300 |

| Type: | Cot 90° |

| Internal diameter, mm: | 180 |

| Tip izolare: | Non-isolated |

| Metal thickness, mm: | 0,5 |

| Stainless steel internal layer, AISI: | 304 |

| Coutry of brand: | Turkey |

| Color: | Silver |

| Scope of application of the chimney: | Boilers, fireplaces, stoves |