Solid fuel boiler with automatic loading STALMARK DUO PID 21 kW

This boiler stands out for its versatility, as the feeder can be installed on either the right or left side, allowing it to be tailored to the user's individual needs. The compact side design ensures convenient adjustment of operating parameters.

Design Features

The DUO-PID boiler is equipped with two combustion systems:

A new-generation cast iron retort burner.

A traditional firebox with a fixed water grate.

Body

The body is made of a bent-welded construction with a water jacket, crafted from certified boiler steel with a thickness of 6 mm.

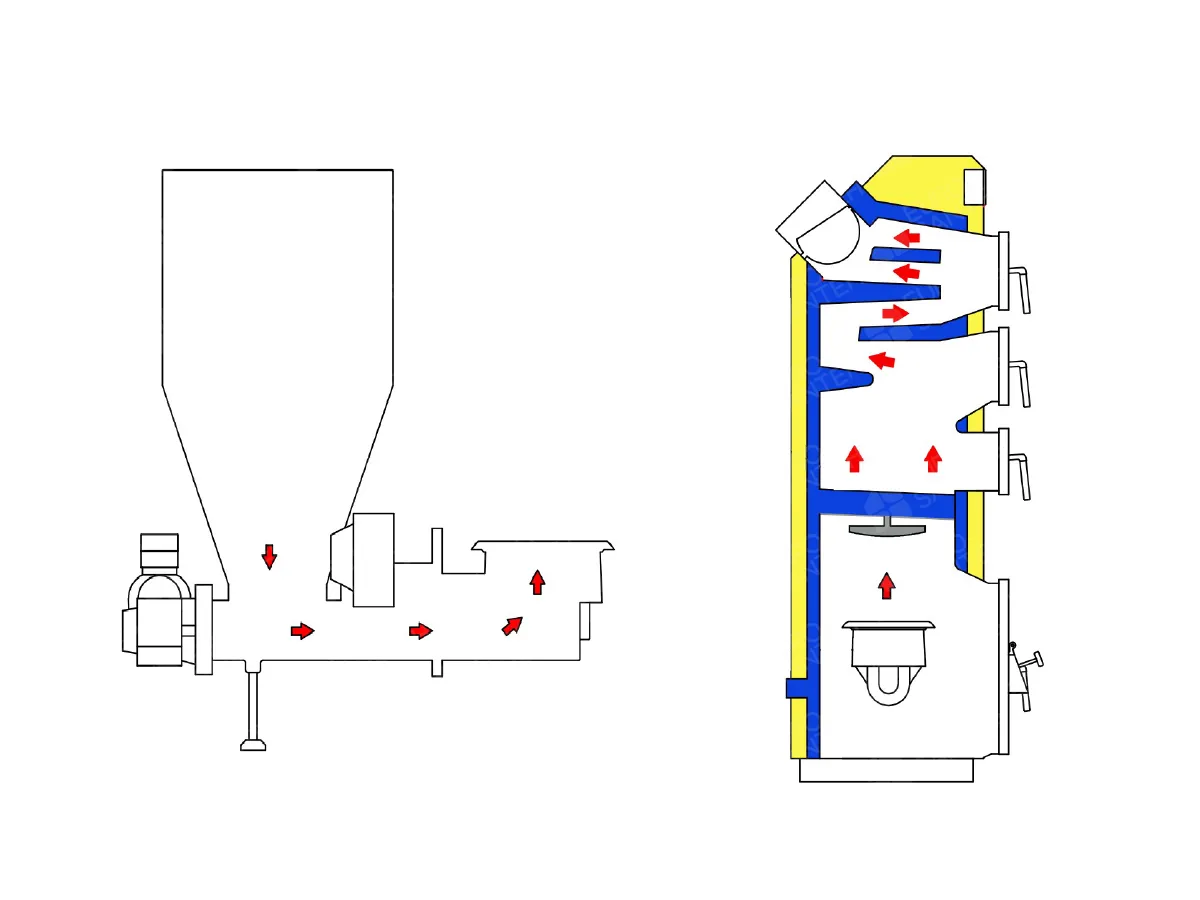

Operation Principle

The combustion process is carried out by automatically feeding fuel into the cast iron retort burner via a screw feeder. Combustion is supported by forced air supply. A built-in cast iron deflector, located above the burner, promotes more complete gas combustion and even heat distribution.

Chimney and Damper

The 45° angled chimney ensures efficient exhaust gas removal. An adjustable damper controls the draft, preventing excessive vacuum.

Water Grate

Allows the use of large-fraction fuel (from 4 cm) and ensures the boiler operates during power outages (provided the heating system is properly designed).

Boiler Control

The standard package includes an ST-750 TECH controller with a PID algorithm and a flue gas temperature sensor.

Controller Functions:

Air supply management.

Control of four pumps (heating, hot water supply, underfloor heating, circulation).

Control of one valve actuator.

Ability to connect three- and four-way valves, as well as Internet/GSM control modules.

Advantages of the STALMARK DUO-PID Boiler

Heat exchanger made of certified steel.

Cast iron burner with a thickness of 6-8 mm and screw fuel feeding.

90% efficiency and high combustion efficiency.

Two combustion systems: automatic and traditional.

45° angled chimney for optimal gas exhaust.

Universal door and the option to install the feeder on either side.

48-month warranty on the heat exchanger's tightness.

24-month warranty on electromechanical components.

Support for summer mode operation.

Controller with PID regulation and Internet/GSM control capabilities.

Configuration Options:

Choice of tank placement – left or right (upon request).

| Power, kW: | 21,0 |

| Heating surface, m²: | 210 |

| Loading type: | Automatic |

| Efficiency, %: | 90 |

| Metal thickness, mm: | 6,0 |

| Hopper volume, l: | 310 |

| Combustion chamber dimensions, mm: | 400x344x270 |

| Boiler water volume, litres : | 72 |

| Weight, kg: | 465,0 |

| The volume of the combustion chamber, l: | 36 |

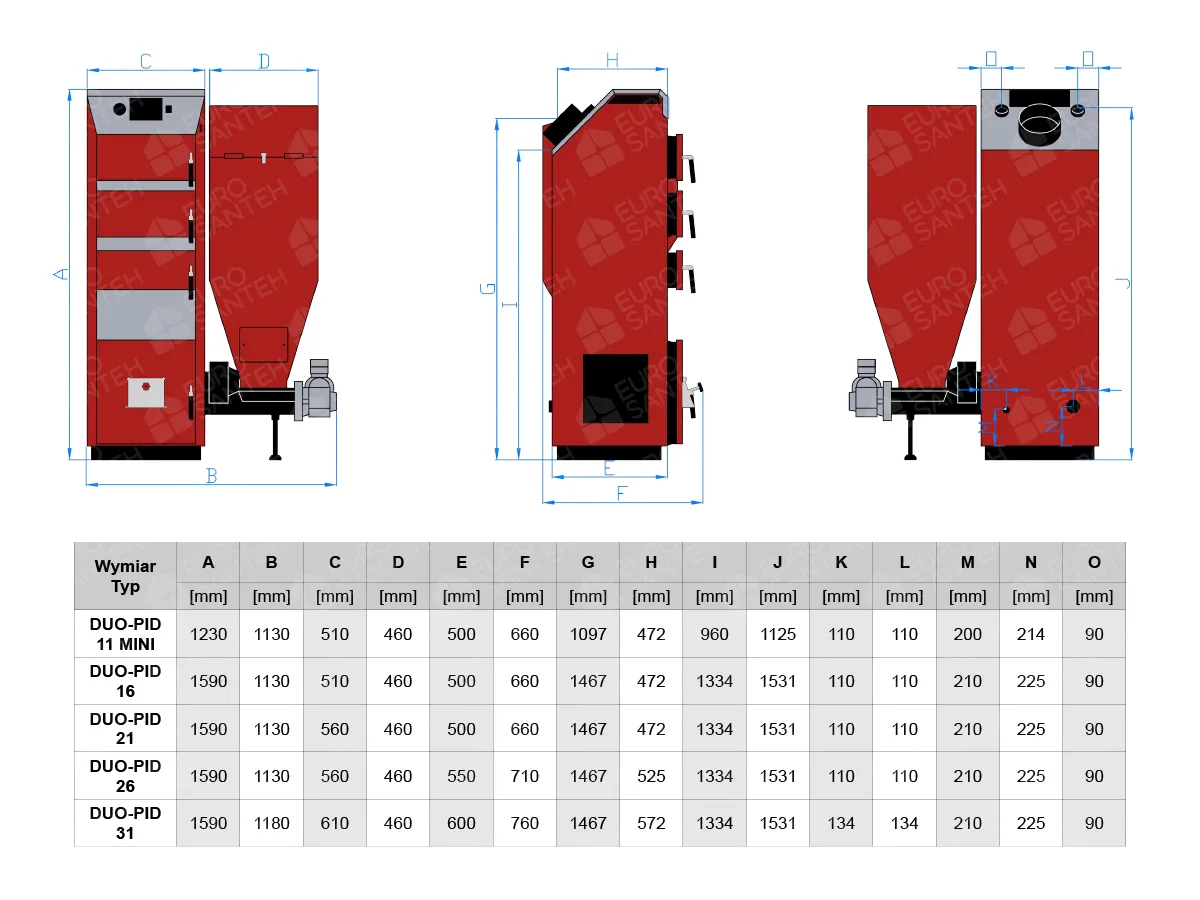

| Height, mm: | 1590 |

| Width, mm: | 1210 |

| Depth, mm: | 700 |

| Maximum pressure, bar: | 1,5 |

| Combustion chamber type: | Open |

| Fuel type: | Solid |

| Chimney diameter, mm: | 180 |

| Number of circuits, units: | 1 |

| Installation method: | On the floor |

| Coutry of brand: | Poland |

| Destination: | Heating |

| Exit from the heating system: | 1 1/2 |

| Entering the heating system: | 1 1/2 |

| Automatic loading: | Yes |