Solid fuel boiler KRONAS ALMAX D 20 kW

The modern KRONAS ALMAX D solid fuel boilers with a power of 20 kW represent an upgraded series of heating units designed for both domestic and industrial use. These boilers stand out due to their ease of operation and high efficiency, providing excellent performance and reliability. The 20 kW model is ideal for heating medium to large-sized spaces.

Solid fuel boilers require connection to an electrical network for operation. However, to ensure functioning without electricity, a mechanical draft regulator can be used, making the equipment independent of external power sources.

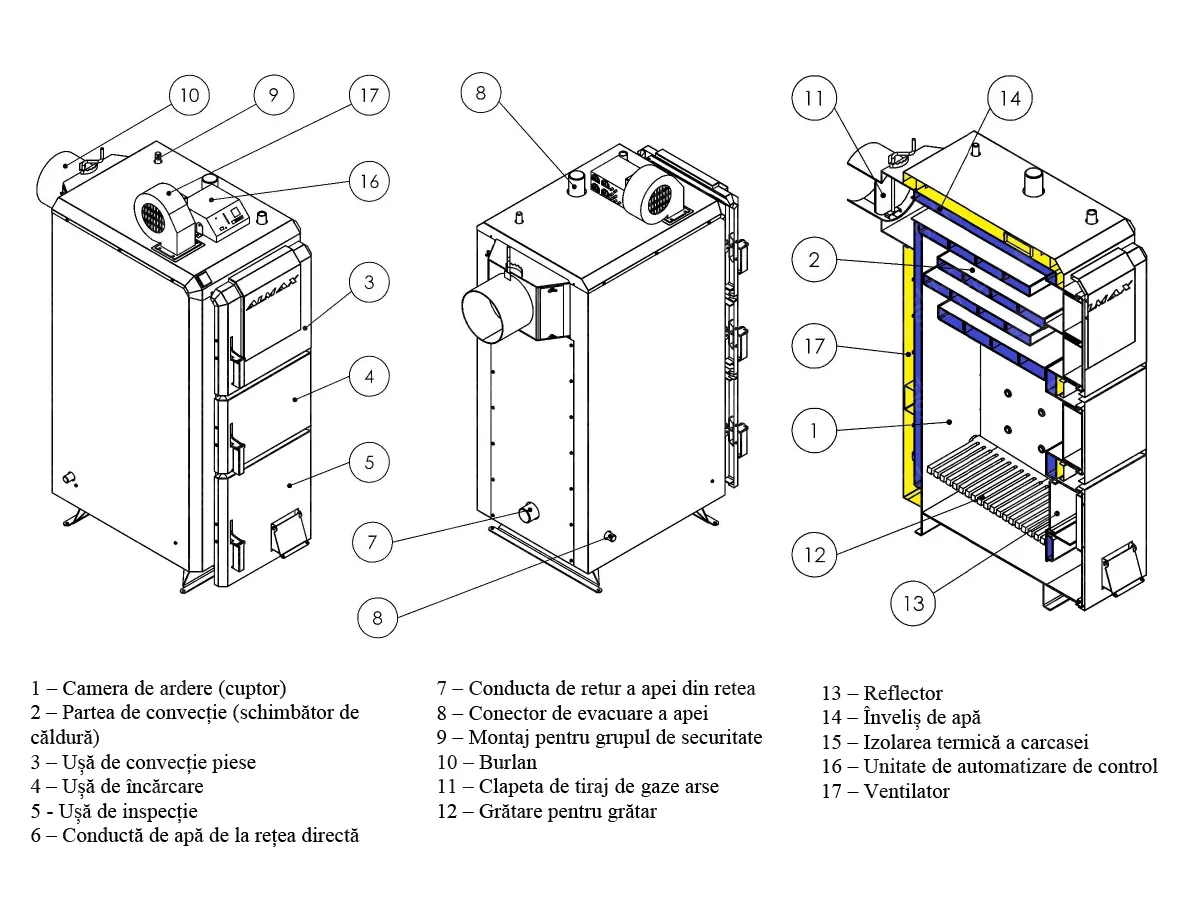

Design Features of the KRONAS ALMAX D 20 kW Boiler:

- Spacious combustion chamber with a volume that varies depending on the boiler's power.

- Four-pass convection heat exchanger for efficient heat transfer.

- Combined grates for easy loading of solid fuel.

- Socket for installing a safety valve or security system, as well as a socket for quick water drainage.

- Multiple doors for easy maintenance: for fuel loading, cleaning the convection part, and inspection doors for servicing the grates and ash pan.

- The possibility to install a pellet burner, turning the boiler into a versatile unit (this requires removing the cast iron grates on both sides of the combustion chamber).

- A controller that continuously monitors water temperature and automatically adjusts the operation of the fan to ensure optimal performance.

Advantages of the KRONAS ALMAX D 20 kW Boilers:

- A wide range of models depending on power and the area to be heated.

- High efficiency – from 86% and higher.

- The ability to operate without electricity using a mechanical draft regulator.

- Efficient heat exchange thanks to the multi-pass convection heat exchanger.

- Modern equipment with a fan and microprocessor control.

- Nozzles for secondary air supply, located around the perimeter of the combustion chamber.

- Double thermal insulation of doors with heat shields.

- Modern and aesthetic design.

- The possibility of converting the boiler to a pellet model by purchasing a burner, feeder auger, and hopper.

- The heat exchanger and the boiler body are made of heat-resistant steel with a thickness of 6 mm, with thermal insulation of the body with a thickness of 5 cm.

Types of Fuel:

- Wood

- Coal (lignite, anthracite)

- Fuel briquettes (sawdust, peat)

- Peat lumps

- Woodworking waste

The boiler’s design ensures high efficiency even when using low-calorie fuels. The highest efficiency is achieved when burning coal.

| Power, kW: | 20,0 |

| Heating surface, m²: | 200 |

| Loading type: | Manual |

| Efficiency, %: | 86 |

| Metal thickness, mm: | 6,0 |

| Boiler water volume, litres : | 72 |

| Weight, kg: | 312,0 |

| The volume of the combustion chamber, l: | 91 |

| Height, mm: | 1370 |

| Width, mm: | 550 |

| Depth, mm: | 950 |

| Maximum pressure, bar: | 2 |

| Combustion chamber type: | Closed |

| Fuel type: | Solid |

| Chimney diameter, mm: | 180 |

| Number of circuits, units: | 1 |

| Installation method: | Vertical |

| Coutry of brand: | Ucraine |

| Destination: | Heating |

| Exit from the heating system: | 2 |

| Entering the heating system: | 2 |

| Automatic loading: | No |