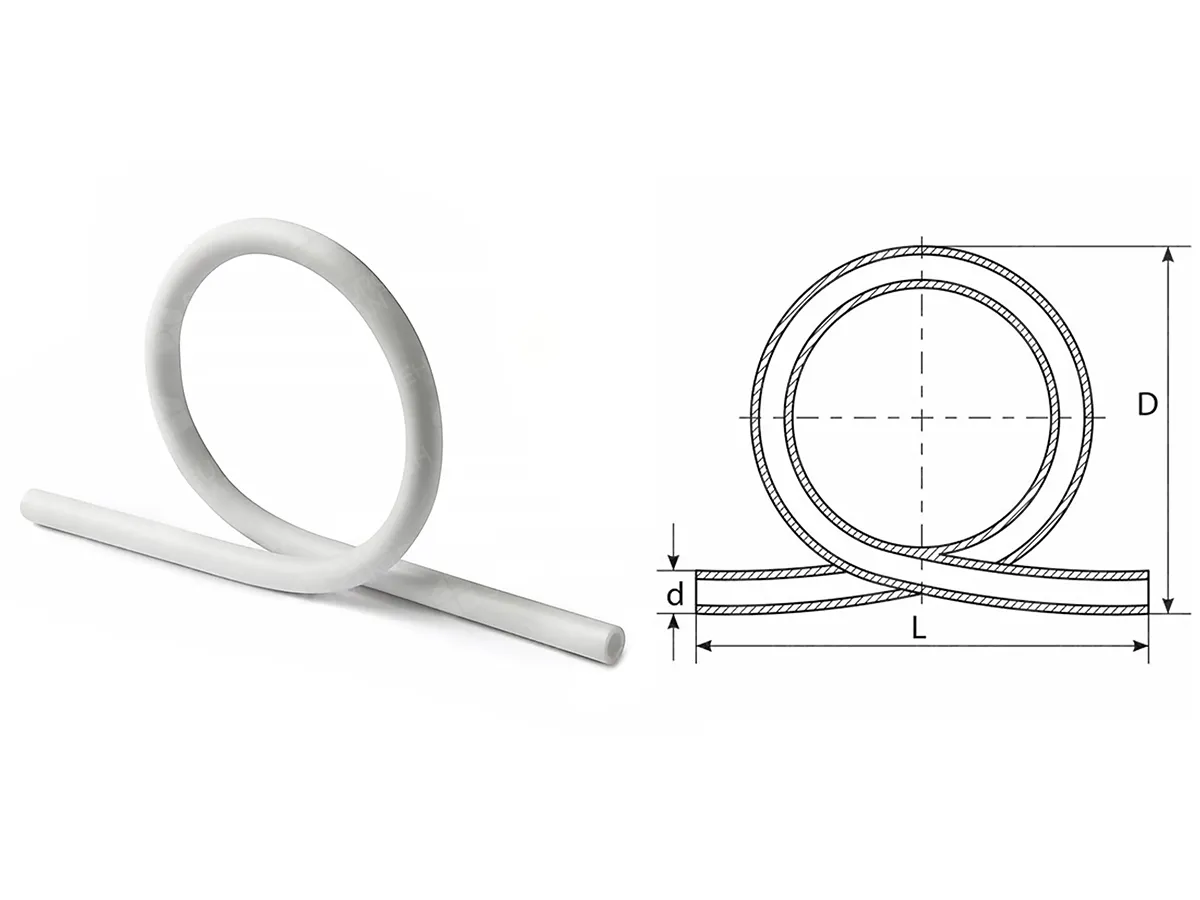

Expansion joints made of polypropylene are important components in piping systems used in various sanitary and industrial installations. These devices are designed to absorb thermal expansion and contraction of pipes, thereby preventing damage that can occur over time due to temperature fluctuations. Next, we will look at the specific characteristics of the polypropylene expansion joint, emphasizing their importance in practical applications.

General characteristics

Type: Polypropylene expansion joint

Expansion joints are available in a variety of types and materials, but this particular model is made from polypropylene, a plastic that offers many benefits due to its chemical and physical properties. Polypropylene is known for its corrosion resistance and ability to withstand variable temperatures, making it ideal for such applications.

Diameter: 25mm

25mm diameter is a common size that provides wide compatibility with many piping systems. This diameter allows adequate fluid flow to be maintained through the system while maintaining the necessary flexibility to absorb expansion and contraction.

Pressure: 16 bar

The compensator is designed for pressures up to 16 bar, which indicates high strength and performance even with intensive use. The ability to cope with this pressure makes this expansion joint suitable for a wide range of applications, including potable water systems, heating systems and various industrial processes.

Material: PPR (Polypropylene Copolymer)

The material used for this expansion joint is PPR, also known as polypropylene copolymer. PPR is known for its excellent resistance to high temperatures and high pressures, making it ideal for use in hot and cold water conveying systems. In addition, PPR has a long service life and is resistant to corrosion, scale and many harsh chemicals. This chemical resistance expands the expansion joint's range of applications to include harsh chemical and industrial environments.

Benefits and Applications

Flexibility and shock absorption

Polypropylene expansion joints offer a high level of flexibility, allowing them to effectively absorb mechanical shock and vibration in the piping system. This is important to maintain the integrity of the system during operation and prevent damage caused by sudden or oscillating movements.

Durability and resistance to extreme conditions

Another important advantage of polypropylene expansion joints is their durability. Polypropylene, and especially PPR, is capable of withstanding a wide range of extreme conditions, including high temperatures and high pressure. This enhanced stability ensures that piping systems equipped with these expansion joints will have a longer service life and require less maintenance compared to other materials.

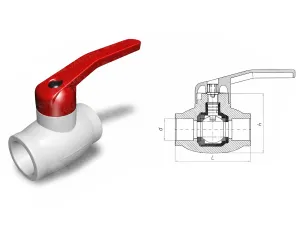

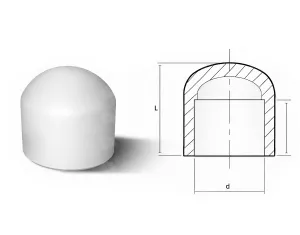

Compatible and easy to install

Polypropylene expansion joints are easy to install due to their design and compatibility with other components of the piping system. Polypropylene is a lightweight material, making it less labor-intensive to handle and install, thereby reducing installation time and costs. In addition, they are compatible with a wide range of pipes and fittings, making them easy to integrate into your existing system.

Conclusion

Polypropylene expansion joints, especially PPR, are important and effective components for any piping system that requires the absorption of thermal expansion and contraction. With a diameter of 25 mm and a pressure rating of up to 16 bar, these expansion joints provide strength, flexibility and high performance. PPR material adds an additional level of reliability and durability, making these expansion joints an excellent choice for a variety of applications, from domestic sanitary installations to complex industrial systems.

| Maximum working pressure, bar: | 16 |

| Type: | Compensator |

| Diameter, mm: | 25 |

| Body material: | PPR |

| Color: | White |

| Ambient temperature, °C: | 0...+50 |