Pipes and fittings

Pipes and fittings form the essential infrastructure of fluid transportation systems, serving as conduits for liquids or gases in various applications. Whether in residential plumbing, industrial facilities, or agricultural setups, the choice and utilization of pipes and fittings play a pivotal role in the seamless operation of the entire system. In this comprehensive exploration, we delve into the significance of these components, offering insights into types, materials, and critical considerations related to pipes and fittings.

Pipes: The Structural Foundation of Fluid Systems:

-

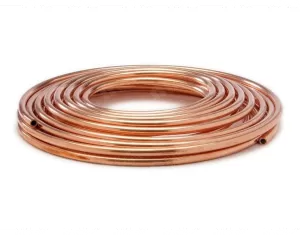

Pipe Materials: The selection of pipe materials is a critical aspect, influencing the durability and performance of the system. Common materials include steel, copper, PVC, and polyethylene, each possessing unique characteristics suitable for specific conditions.

-

Pipe Diameter: Choosing the correct pipe diameter depends on the volume of fluid to be transported. Incorrect sizing can impact flow rates and system pressure.

-

Types of Pipes: Pipes can be straight or coiled, serving diverse functions such as conveying potable water, draining wastewater, or transporting gases.

-

Corrosion Resistance: Depending on the fluid's chemical properties, pipes should be corrosion-resistant to prevent premature aging and material wear.

Fittings: Vital Connection Elements:

-

Diversity of Fittings: Fittings encompass a wide array of components such as elbows, reducers, couplings, and joints. These are essential for creating the necessary connections in the system.

-

Fitting Materials: Fittings can be crafted from brass, stainless steel, PVC, or alloys tailored for strength and durability based on requirements.

-

Types of Connections: Fittings can be threaded, welded, pressed, or glued, offering a variety of options for proper assembly of the system.

-

Application-Specific Fittings: Specialized fittings exist for various applications, such as those designed for heating systems, plumbing installations, or gas distribution networks.

Pipes and Fittings: A Perfect Symbiosis in the System:

-

Material Compatibility: Ensuring compatibility between the pipe material and fittings is crucial to prevent undesirable chemical reactions or corrosion at their interface.

-

Sealability and Durability: Proper fitting installation ensures the sealing of connections, preventing leaks and contributing to the durability of the system.

-

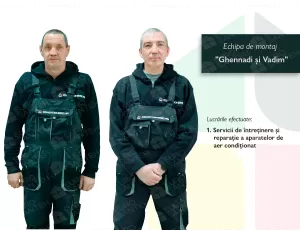

Professional Installation: Proper installation requires technical expertise. It is advisable to enlist the services of a professional to avoid issues related to assembly.

Purchasing Pipes and Fittings:

-

Specialized Stores: Specialized stores offer a diverse range of pipes and fittings, with knowledgeable staff providing valuable advice.

-

Construction Companies: Construction and plumbing companies can provide comprehensive solutions, including materials and installation services.

-

Online Retailers: Purchasing pipes and fittings online provides convenience and the opportunity to compare products and prices.

-

Authorized Distributors: Approach authorized distributors of recognized manufacturers to ensure product quality and compliance with standards.

Tips for Maintenance and System Enhancement:

-

Regular Inspection: Conduct periodic inspections to identify potential leaks, corrosion, or other issues that may affect system performance.

-

Replacement of Worn Components: Replace any pipes or fittings showing signs of wear or deterioration to avoid major problems.

-

Monitoring Pressure and Flow: Keep an eye on system pressure and flow rates. Adjust as needed to maintain system efficiency.

-

Anti-Corrosion Preservation: Use anti-corrosion preservation methods in areas with hard water or other conditions that can accelerate material deterioration.

Conclusion: Stability and Efficiency with Quality Pipes and Fittings:

In conclusion, pipes and fittings represent the fundamental elements for constructing robust and reliable fluid transportation systems. The choice of appropriate materials, proper installation, and regular maintenance are key to ensuring efficient and durable system operation. With careful consideration and expertise, you can create a system tailored to your needs, providing safety and efficiency across applications, from residential settings to complex industrial environments.