Insulated 135° chimney tee SOLINOX Ø200–250 (inox 316/304)

The insulated 135° chimney tee SOLINOX Ø200-250 (inox 316L/304) is a double-wall “sandwich” flue component used to connect a vertical run to a horizontal (or inclined) section of a smoke-exhaust system. It is chosen when a branch must be created without sacrificing draft and with maximum protection against condensate. The 135° angle delivers a smoother flow turn than a 90° tee, which means lower resistance and typically more stable draft—especially on complex routes and when the appliance operates below full output.

The sandwich-tee construction has two shells: the inner liner is made of stainless steel inox 316L, while the outer casing is inox 304. This material combination is practical and well justified: the inner surface is the one exposed to hot flue gases and condensate, so 316L provides enhanced resistance to acidic environments and corrosion. This is particularly important where “acidic” condensate is likely (frequent start/stop cycles, shoulder seasons, lower flue-gas temperatures, certain fuel types). The 304 outer shell retains strength and a neat appearance and helps keep the product cost-effective without compromising reliability.

The key advantage of an insulated tee is thermal stability. The insulation layer between the walls limits flue-gas cooling, reducing the likelihood of condensate formation right in the turn/branch area—where “cold spots” most often occur. Insulation also improves safety: the outer surface heats up less, which matters when the flue passes near temperature-sensitive structures. As a result, the system runs more evenly, produces fewer “wet” deposits, and is easier to maintain.

The Ø200-250 range is convenient for systems with an enlarged main-channel cross-section or where the design requires joining sections of different diameters. This tee is used when connecting higher-output boilers, stoves, and fireplaces, and for chimney upgrades where a proper, reliable tie-in to the vertical line is required.

Installation is performed using a socket (spigot-and-socket) connection: assembly is quick and straightforward, and joints remain tight when the components are oriented correctly. In most cases, nodes are additionally secured with clamps, and where needed, heat-resistant chimney-rated sealing materials are used. This approach helps prevent air ingress, condensate leakage, and loss of tightness during repeated heating/cooling cycles.

A key installation rule should be emphasized: beneath the tee, in the lower section, an inspection piece, an end cap, or a condensate collector must be installed. This is a mandatory service zone—ideal for soot removal, channel condition checks, and safe moisture drainage. The insulated tee further reduces the risk of condensate flowing back toward the heating appliance and helps maintain correct chimney operating conditions.

SOLINOX 135° Ø200-250 (inox 316L/304) is the choice for those who need a sandwich-chimney configuration with maximum resistance to condensate and corrosion. The smooth 135° angle, double-wall design, and 316L inner liner make this tee a strong solution for a durable, safe, and service-friendly smoke-exhaust system.

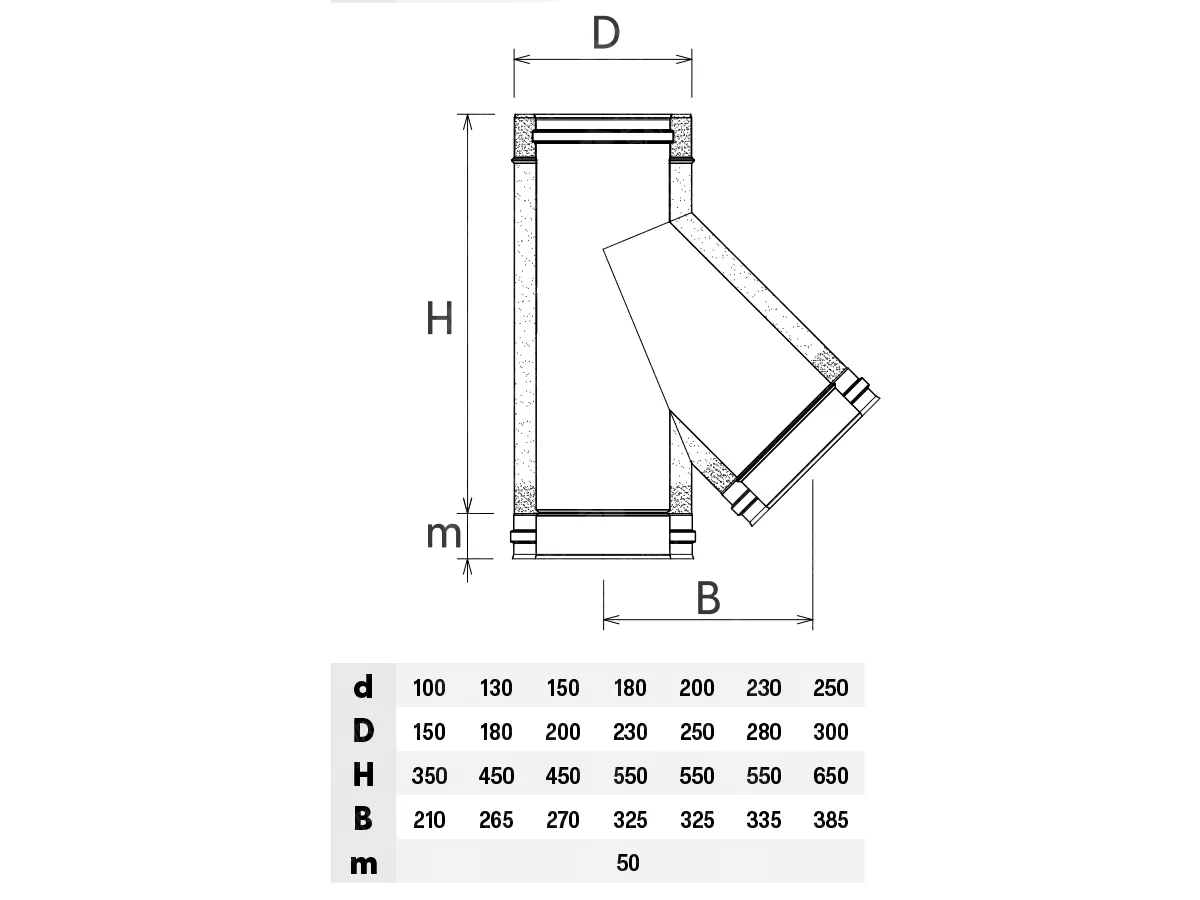

| Operating temperature, °C: | +200...+300 |

| Type: | Chimney tee 45°/135° |

| Internal diameter, mm: | 200 |

| Tip izolare: | Isolated |

| External diameter, mm: | 250 |

| Stainless steel internal layer, AISI: | 316 |

| External layer stainless steel, AISI: | 304 |

| Coutry of brand: | Turkey |

| Color: | Silver |

| Scope of application of the chimney: | Boilers, fireplaces, stoves |