Boiler installation

Boiler installation is a pivotal step in establishing an efficient heating system for your home. From selecting the right equipment to professional installation, each stage plays a crucial role in providing warmth and thermal comfort. This comprehensive guide will explore the key aspects of boiler installation, its benefits, and how it contributes to creating a cozy and energy-efficient living space.

Key Stages of Boiler Installation:

Initial Assessment: The process begins with a thorough assessment of your heating needs, the size of the property, and the most suitable type of boiler. This initial evaluation is essential for determining the right system for optimal performance.

Selecting the Right Boiler: Choosing the right boiler is critical for efficiency. Factors such as fuel type, size, and energy efficiency ratings are considered during this stage to ensure the selected boiler meets the specific requirements of your home.

Site Preparation: Before installation, the site needs to be prepared. This involves assessing the location for optimal boiler placement, ensuring proper ventilation, and making any necessary adjustments to accommodate the new heating system.

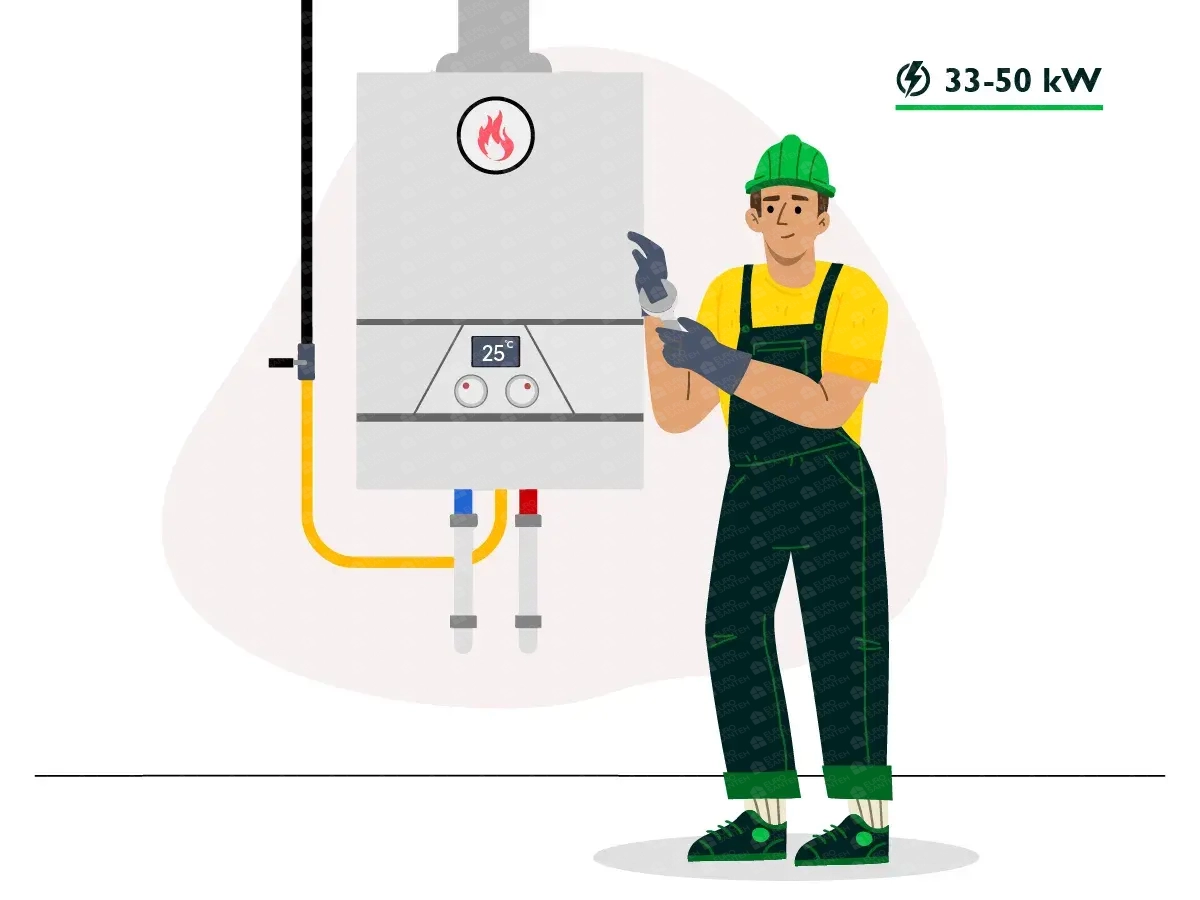

Professional Installation: The actual installation is a task best left to professionals. Licensed technicians will connect the boiler to the existing heating system, install necessary piping, and ensure all safety measures are in place. Proper installation is crucial for the boiler's longevity and efficient operation.

Testing and Commissioning: After installation, rigorous testing is conducted to verify that the boiler operates as intended. This includes checking for leaks, ensuring proper pressure levels, and fine-tuning the settings for optimal performance.

Benefits of Boiler Installation:

Efficient Heating: Boilers are known for their efficiency in providing consistent and even heating throughout the home. They distribute warmth effectively, eliminating cold spots.

Energy Savings: Modern boilers are designed with energy efficiency in mind, leading to significant cost savings on energy bills. This makes them a sustainable and economical choice for homeowners.

Reliability and Durability: Professionally installed boilers are reliable and durable, requiring minimal maintenance when operated under optimal conditions. Regular servicing enhances their longevity.

Improved Comfort: Boilers offer precise control over the heating process, allowing homeowners to maintain a comfortable temperature. Radiant heat from boilers creates a cozy atmosphere.

Maintenance Tips:

Regular Servicing: Schedule annual maintenance checks to ensure your boiler operates at peak efficiency. Professional servicing helps identify and address potential issues before they escalate.

Bleeding Radiators: Periodically bleeding radiators ensures that the system remains free of air pockets, promoting efficient heat distribution.

Environmental Considerations:

Green Boiler Options: Consider eco-friendly boiler options that use sustainable energy sources, such as biomass boilers or those designed to work with renewable technologies.

Proper Disposal: When replacing an old boiler, ensure proper disposal or recycling of the old unit to minimize environmental impact.

Conclusion:

Boiler installation is not just about having a reliable heating system; it's about creating a warm and inviting home. Professional installation and regular maintenance are essential for optimal performance and efficiency. Invest in a quality boiler, and enjoy the benefits of efficient heating and lasting comfort in your living space.