Main characteristics:

The devices are designed for air purification with a maximum dust concentration of up to 0.5 mg/m³.

The air temperature range supplied to the device varies from -20℃ to +40℃ at a maximum humidity of no more than 19 g/kg.

The filters effectively capture at least 70% of PM2.5 dust particles. Due to the increased filtration area, F7 class filters provide low airflow resistance and have a long service life.

Purpose: F7 class duct filters are intended to ensure high-quality air purification in various types of buildings, including residential houses, commercial facilities, public institutions, and industrial premises. The F7 DN315 filter model is compatible with the KNP 1000 Perfect and KNP 1500 Perfect ventilation units.

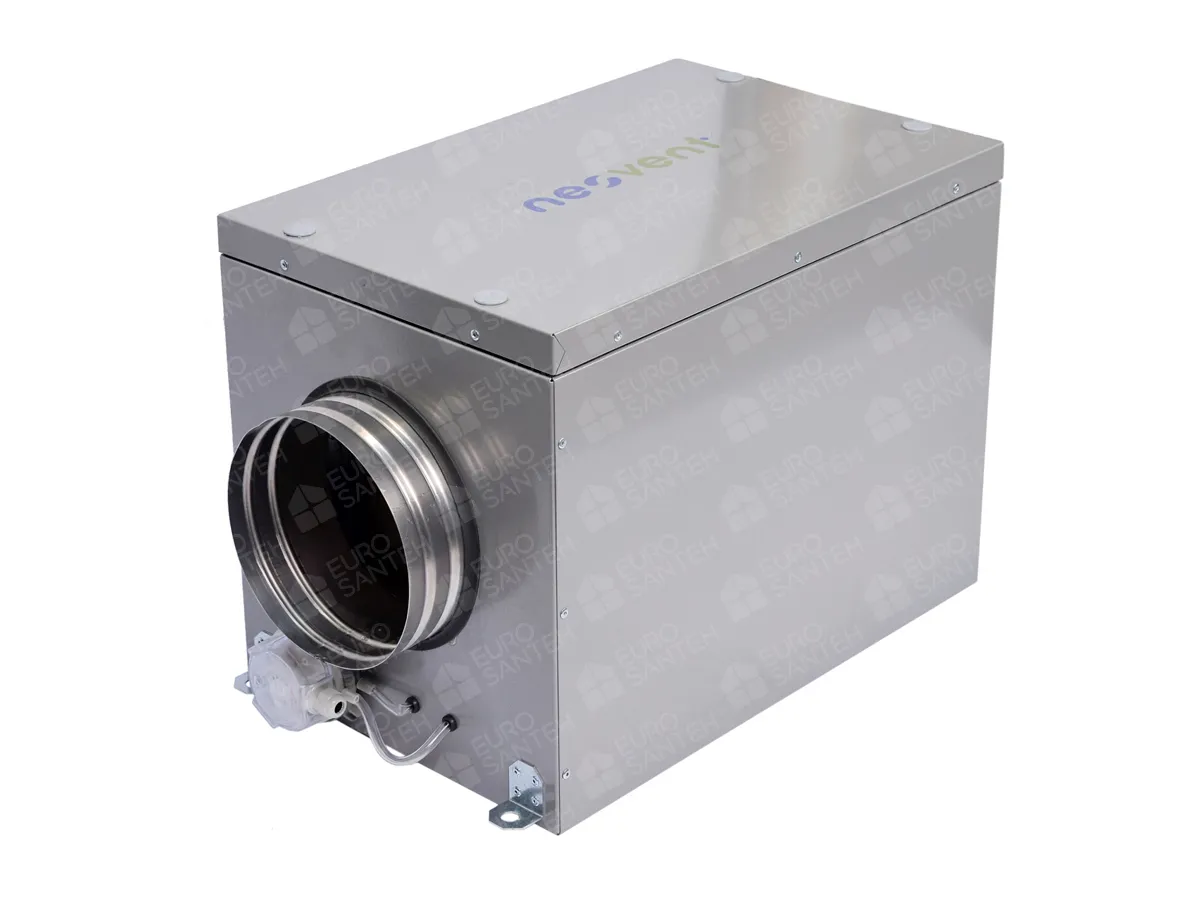

Construction: Duct filters are equipped with an insulated housing, air filtering element, pressure relay to control the contamination level, mounting brackets, and inspection hatch. The filters should be installed in supply air ducts, avoiding areas with high dust levels, such as rooms where plastering or floor sanding is carried out.

Service life: To maintain efficient system operation, it is recommended to check F7 filters every 3 months and replace them every 6 months, regardless of their visible condition. The built-in pressure sensor monitors pressure drops in the system and timely signals the need to replace the filtering element.

Advantages:

High efficiency in cleaning air from fine dust particles and pollutants.

Extended service life due to low airflow resistance.

Convenient filter condition control with the pressure relay and inspection hatch.

Compatibility with popular ventilation unit models.

| Filter dimensions, mm: | 592x287 |

| Air flow, m³/h: | 1000 |

| Average dust retention capacity, %: | 70 |

| Weight, kg: | 22,0 |

| Cleaning class: | Fine - F7 |

| Body material: | Metal |

| Filter type: | Duct |

| Ambient temperature, °C: | -20...+40 |

| Sizes, mm: | 656x415x531 |

| Filter change frequency, month: | 3-6 |