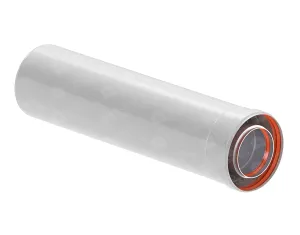

Coaxial angle for exhausting condensate from the chimney, diameter 60/100 mm, 90°

A coaxial 90° elbow with a diameter of 60/100 mm is designed to change the direction of the flue in a condensing boiler system, providing flexibility and ease of installation. The production process utilizes fully automated technology: welding is performed by robotic equipment, ensuring high precision in connections and complete airtightness. After welding, the components undergo cleaning, anti-corrosion treatment, and thermal exposure at a temperature of 180°C. The final painting in an automated chamber gives the product resistance to moisture, acidic condensate, and external influences.

Functional Features and Purpose

The coaxial elbow is a crucial component in the exhaust gas removal system of condensing boilers. It connects the flue pipes to the boiler and directs the flow of exhaust gases and air in the desired direction.

The design of a coaxial flue consists of two pipes of different diameters, one nested inside the other. The inner channel is responsible for venting low-temperature exhaust gases, while the outer channel supplies fresh air for combustion. In condensing systems, due to the low temperature of the exhaust gases, condensate forms inside the pipe, which must be drained through a special drainage system.

Advantages of the Coaxial Elbow for Condensing Boilers

Resistance to Acidic Condensate – The inner pipes are made of materials resistant to aggressive environments (stainless steel or special plastic).

Airtightness and Durability – High-quality seals prevent leaks of condensate and exhaust gases, extending the lifespan of the entire system.

Optimization of Boiler Efficiency – Preheating the incoming air reduces gas consumption and increases the efficiency of the heating system.

Safe Operation – The outer pipe prevents surface heating, making installation possible even in residential spaces and wooden houses.

Compatibility with Various Configurations – Suitable for both horizontal and vertical installation of coaxial flues.

Application of Coaxial Elbows in Condensing Systems

Coaxial flues are used in gas condensing boilers with closed combustion chambers, ensuring efficient removal of exhaust gases and condensate. They are suitable for both wall-mounted and floor-standing boiler models, creating safe and energy-efficient operating conditions.

Thanks to its robust construction, resistance to acidic condensate, and ease of installation, the coaxial 90° elbow with a diameter of 60/100 mm is a reliable solution for organizing an effective flue gas removal system in condensing boilers.

| Type: | Cot |

| Body material: | Galvanized steel |

| Chimney diameter, mm: | 60/100 |

| Coutry of brand: | Italy |

| Type of boiler: | Condensing |

| Angle: | 90° |