The 135° chimney tee SOLINOX Ø180 in stainless steel inox 304 is a connecting component for a single-wall flue system, used to route a branch line neatly into the main vertical chimney. A 135° angle is selected when a “softer” change in airflow direction is desired: flue gases pass the turn without abrupt deceleration, so draft is typically more stable than in a 90° configuration.

The product is made of AISI 304 stainless steel (inox 304), 0.5 mm thick. This material tolerates high temperatures well, resists humidity and everyday corrosion, maintains its geometry under heat, and does not require painting. The single-wall design is suitable for indoor installation, inside an existing shaft, or as an insert/section of the system for transitions and connections.

Installation uses a socket (spigot-and-socket) joint: components are connected “in the direction” of flue-gas flow, which simplifies assembly and helps achieve a tight fit. The SOLINOX Ø180 tee is used in flue-gas evacuation systems for solid-fuel and gas boilers, stoves, fireplaces, and sauna heaters (in compliance with appliance manufacturer requirements and chimney regulations). The 180 mm diameter is selected according to the heat generator outlet and the flue design calculation.

The lower branch of the tee serves as a service zone. An inspection section for cleaning, an end cap, or a condensate collector is installed beneath the tee — providing access to soot deposits and enabling moisture control. If the branch connects to an inclined or horizontal run, this layout makes maintenance easier and reduces the risk of blockages.

The engineering trade-off is straightforward: a 135° angle provides a smoother turn and lower flow resistance, but it requires a bit more space along the route. That is why this tee works best where there is enough room and the priority is steady draft and more predictable system behavior during start-up.

Inox 304 is suitable for most standard operating conditions. If operation involves higher-sulfur fuel, frequent start/stop cycles, and pronounced acidic condensate, 316L is more often considered; otherwise, 304 is a practical choice in terms of durability and cost. For joint tightness, use clamps, a heat-resistant sealing cord, or a chimney-rated sealant, and allow for thermal expansion in accordance with installation rules.

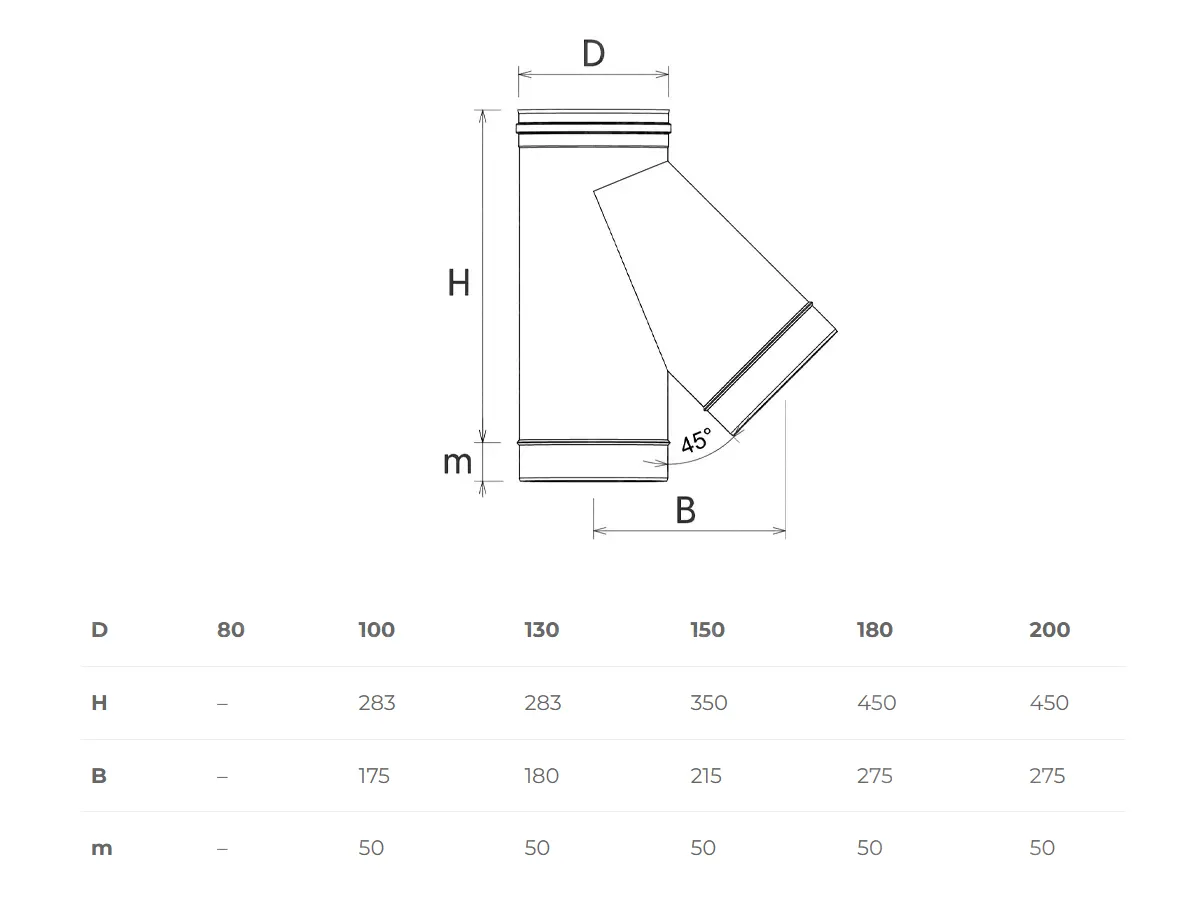

| Operating temperature, °C: | +200...+300 |

| Type: | Chimney tee 45°/135° |

| Internal diameter, mm: | 180 |

| Tip izolare: | Non-isolated |

| Metal thickness, mm: | 0,5 |

| Stainless steel internal layer, AISI: | 304 |

| Coutry of brand: | Turkey |

| Color: | Silver |

| Scope of application of the chimney: | Boilers, fireplaces, stoves |